Separative Work Units (SWU) represent one of the most critical yet complex measurements in the nuclear fuel cycle, quantifying the effort required to separate uranium isotopes during the enrichment process 12. Understanding SWU is essential for grasping how nuclear fuel is prepared and how enrichment facilities operate at an industrial scale 34. This comprehensive analysis explores the fundamental concepts, calculations, and global implications of SWU in modern nuclear energy production 56.

Diagram illustrating the six main stages of the nuclear fuel cycle, highlighting enrichment as a central step.

The Nuclear Fuel Cycle Context

Natural uranium contains only 0.711% of the fissile isotope uranium-235, while most nuclear reactors require fuel enriched to 3-5% U-235 concentration 12. The enrichment process sits at the heart of the nuclear fuel cycle, transforming natural uranium into reactor-ready fuel through sophisticated industrial processes 78. This transformation requires significant energy input and precise engineering to achieve the desired isotopic concentrations 910.

The enrichment step represents approximately half the cost of nuclear fuel and about 5% of the total cost of electricity generated from nuclear power 211. Modern enrichment facilities must balance economic efficiency with technical precision to meet global demand for enriched uranium 512.

What Are Separative Work Units?

A Separative Work Unit (SWU) is not a measure of energy in the traditional physics sense, but rather a complex unit that quantifies the amount of isotopic separation work performed during uranium enrichment 13. The concept was introduced by physicist Paul Dirac in 1941 and has since become the standard measure for enrichment services worldwide 113.

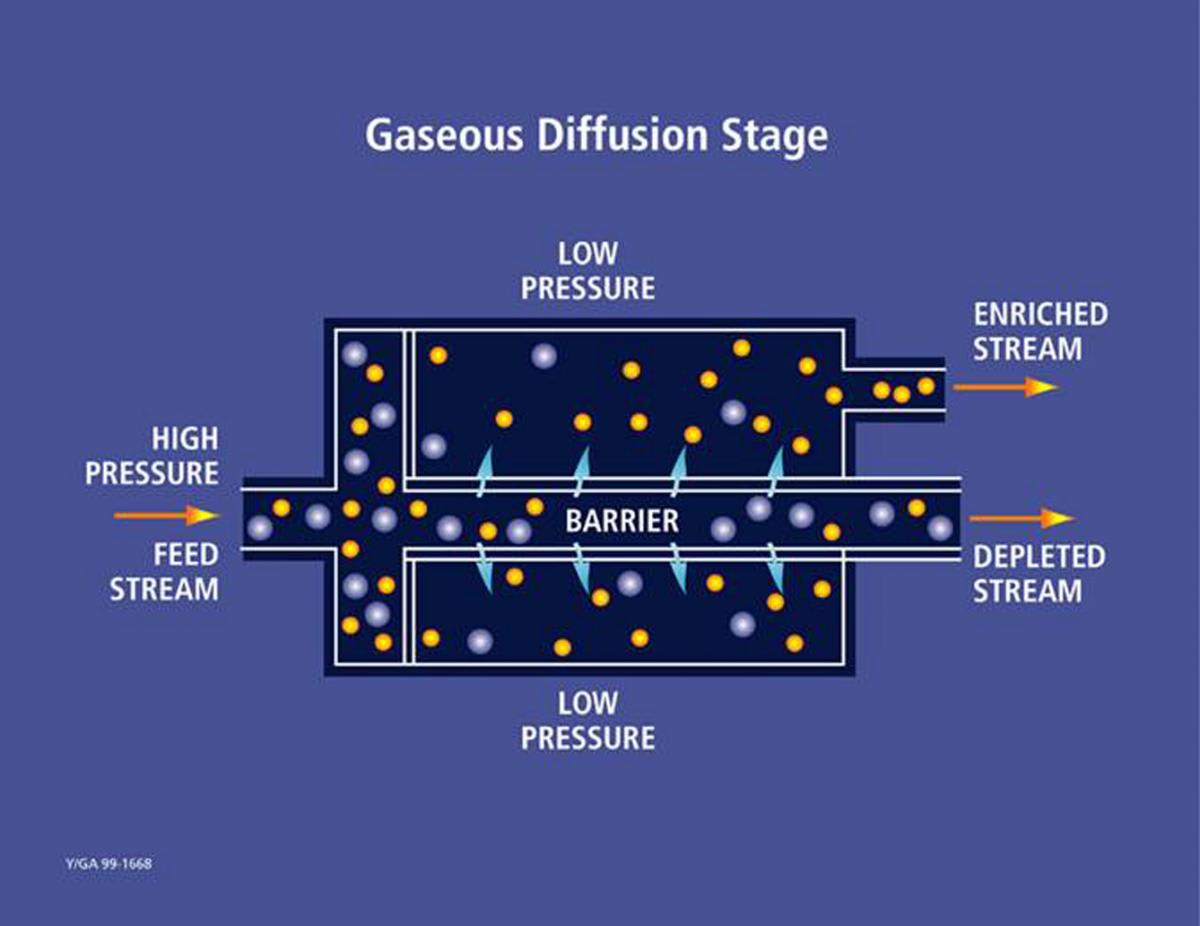

Diagram illustrating a single stage of the gaseous diffusion process used for isotope separation, showing the creation of enriched and depleted streams.

SWU calculations incorporate three critical variables: the concentration of uranium-235 in the feed material, the desired concentration in the enriched product, and the concentration remaining in the depleted uranium or “tails” 114. Each SWU represents a specific quantity of separative work when feed, product, and tails quantities are expressed in kilograms 139.

The unit is strictly defined as the kilogram Separative Work Unit, measuring the quantity of separative work performed relative to the mass of material processed 914. In commercial applications, SWU is often expressed in larger units such as tonnes SWU (tSWU) or kilotonnes SWU (ktSWU) to accommodate industrial-scale operations 16.

The Mathematical Foundation

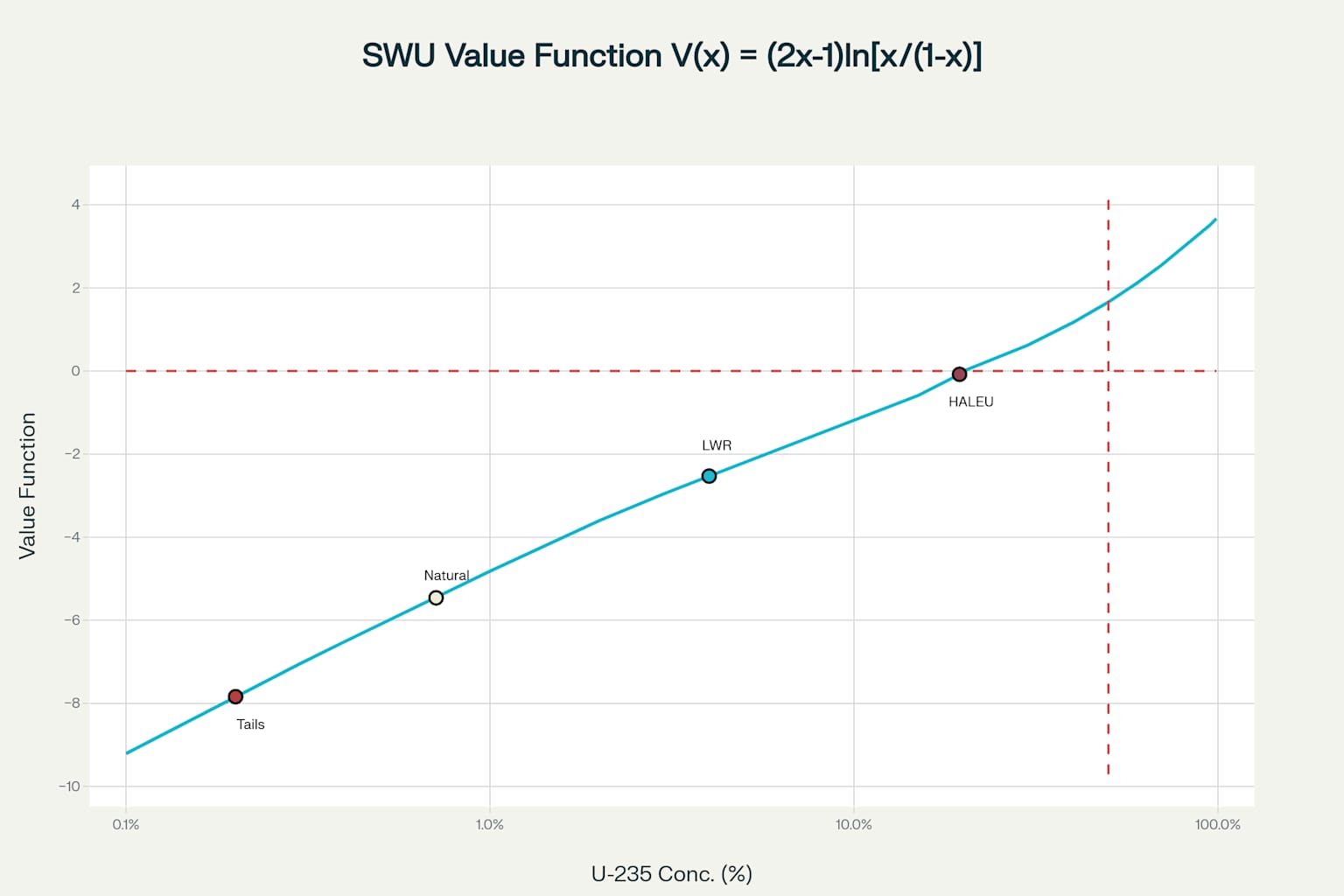

The mathematical foundation of SWU relies on the value function, a thermodynamic intensive quantity that expresses the energy input required to decrease the entropy of uranium samples during isotopic separation 414. This value function ensures that SWU calculations remain independent of concentration levels across different enrichment scenarios 315.

SWU Value Function Curve

The SWU calculation follows the equation: SWU = P·V(xp) + T·V(xt) - F·V(xf), where P represents product mass, T represents tails mass, F represents feed mass, and V(x) is the value function defined as V(x) = (2x-1)ln(x/(1-x)) 114. This mathematical relationship allows precise calculation of enrichment requirements for any desired product specification 315.

For practical applications, a typical example shows that producing 10 kilograms of 4.5% enriched uranium from 102 kilograms of natural uranium requires approximately 62 SWU, with a tails assay of 0.3% 19. These calculations form the basis for all commercial enrichment contracts and facility planning 1611.

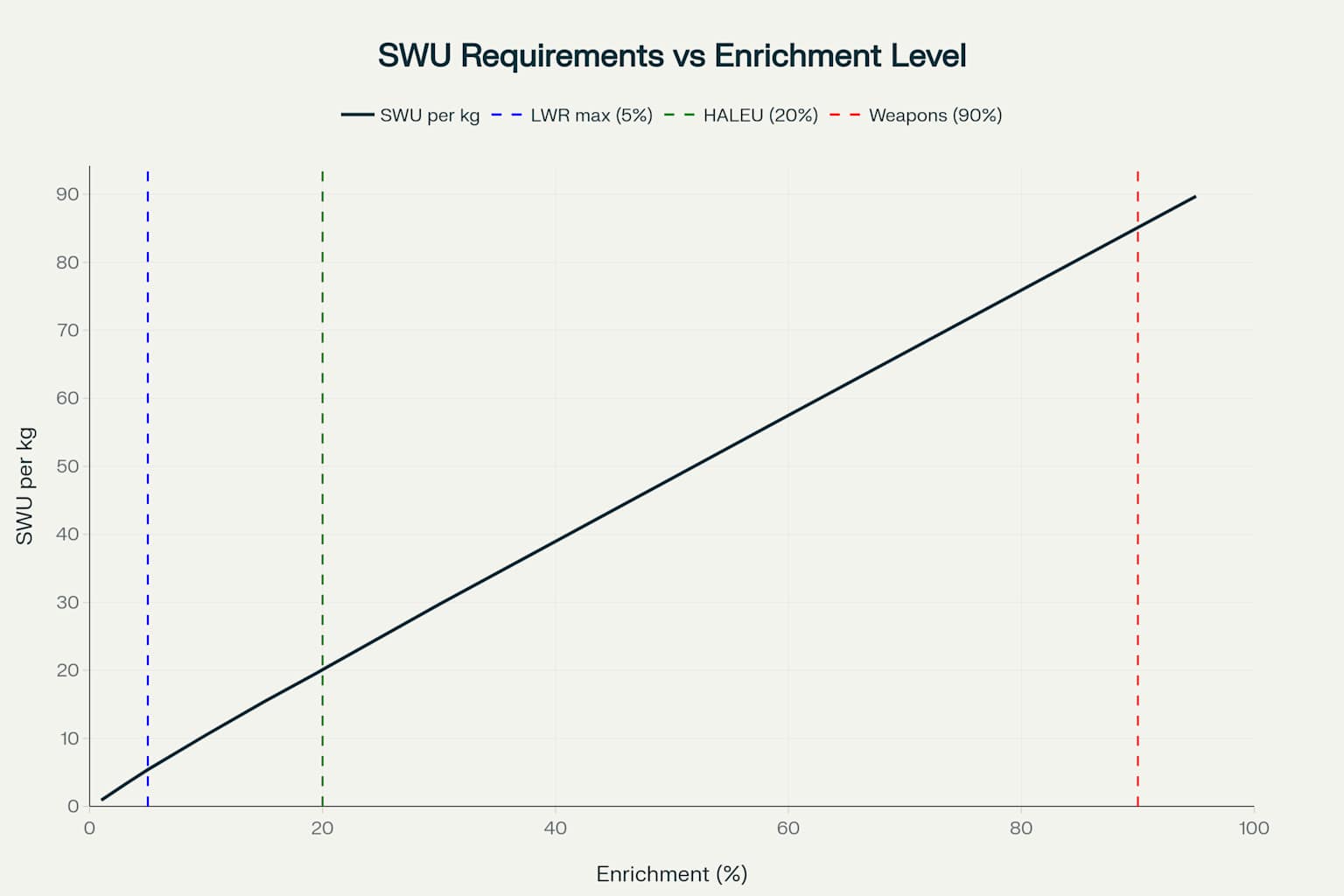

SWU Requirements Across Enrichment Levels

The relationship between enrichment level and SWU requirements follows an exponential curve, with dramatically increasing separative work needed at higher enrichment levels 17. Low-enriched uranium (LEU) for conventional reactors requires modest SWU inputs, while high-assay LEU (HALEU) and highly enriched uranium (HEU) demand substantially more separative work 418.

SWU Requirements by Enrichment Level

Commercial nuclear reactors typically use uranium enriched to 3-5% U-235, requiring approximately 4-8 SWU per kilogram of enriched product 1819. Advanced reactor designs increasingly utilize HALEU fuels enriched between 5-20% U-235, significantly increasing SWU requirements per unit of fuel 20. Research reactors and naval propulsion systems may require even higher enrichment levels, with corresponding increases in separative work 1721.

The proliferation sensitivity of enrichment technology stems from this mathematical relationship, as the relative SWU increment needed to progress from reactor-grade to weapons-grade uranium is substantially less than the initial enrichment effort 1721. This characteristic makes enrichment facilities subject to strict international safeguards and monitoring 220.

Economic Trade-offs in Enrichment

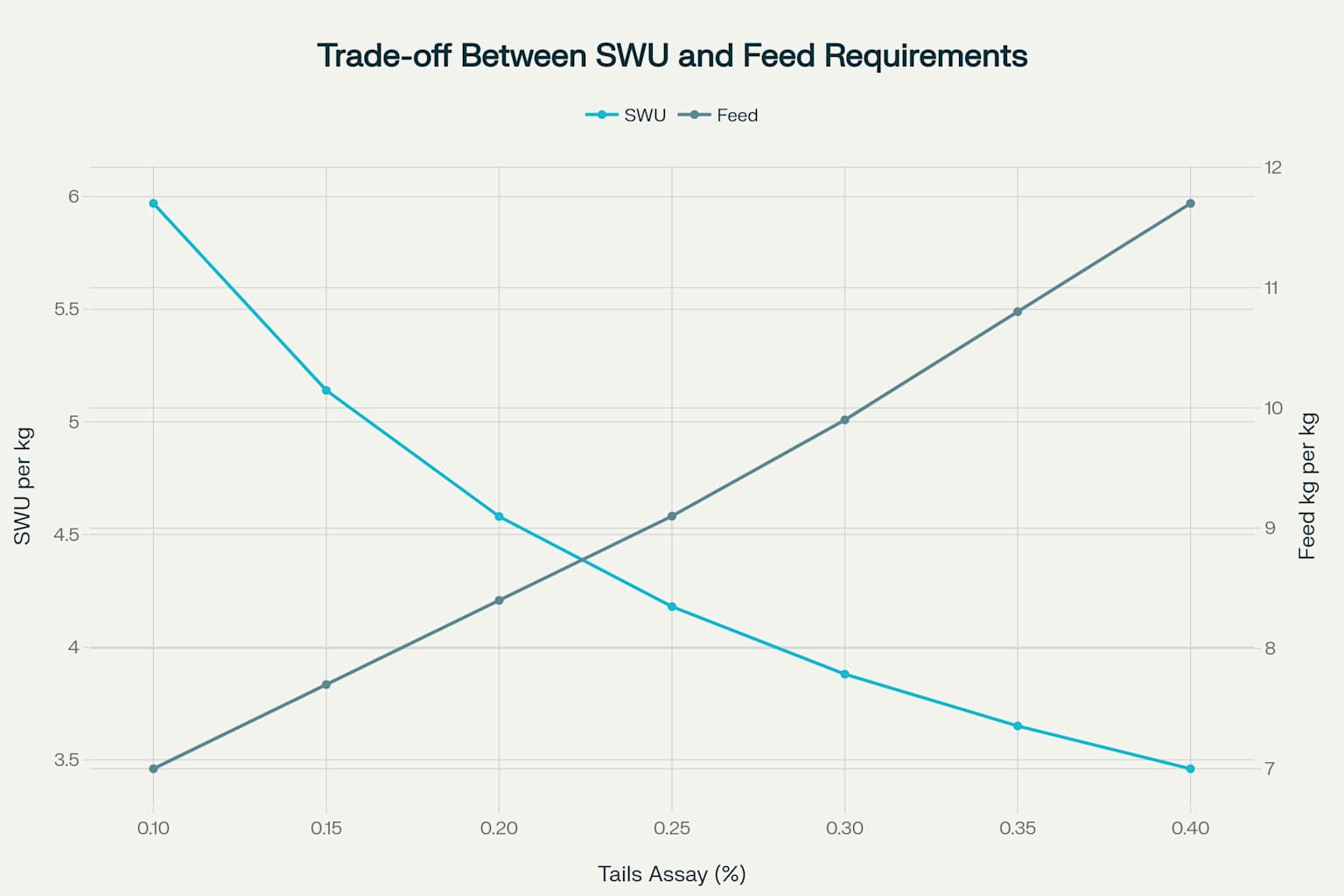

Enrichment facilities face fundamental economic trade-offs between SWU consumption and natural uranium feed requirements, with tails assay serving as the key optimization parameter 1612. Lower tails assays extract more uranium-235 but require additional separative work, while higher tails assays reduce SWU needs but increase feed uranium consumption 1016.

Trade-off Between SWU Requirements and Feed Usage in Uranium Enrichment

Market conditions determine optimal tails assay levels, with facilities adjusting operations based on relative prices of natural uranium and enrichment services 1611. When uranium prices are high, enrichers typically operate at lower tails assays to minimize feed requirements, while low uranium prices favor higher tails assays to reduce SWU consumption 1016.

The practice of “underfeeding” allows enrichers to optimize operations by operating at tails assays lower than contracted levels, generating surplus natural uranium for independent sale 216. Conversely, “overfeeding” requires enrichers to supplement customer-supplied uranium with their own material when operating at higher tails assays 216.

Physical Infrastructure and Technology

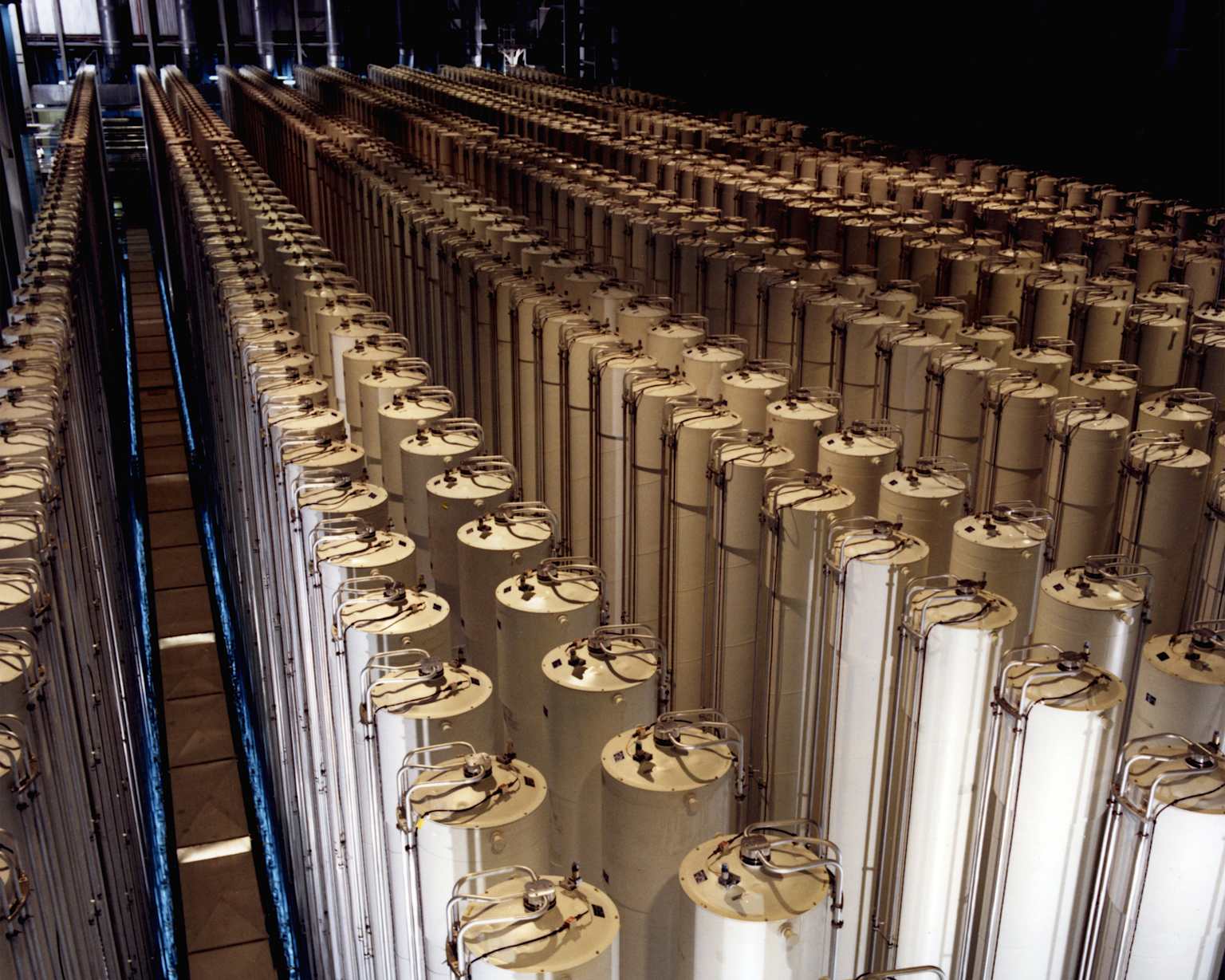

Modern uranium enrichment relies almost exclusively on gas centrifuge technology, which offers superior energy efficiency compared to historical gaseous diffusion processes 220. Gas centrifuge plants require only 50-60 kilowatt-hours per SWU, compared to 2,400-2,500 kilowatt-hours per SWU for gaseous diffusion facilities 19.

A vast array of gas centrifuges arranged in a cascade for uranium enrichment.

Individual centrifuges operate at extremely high speeds, with rotors spinning at 50,000-70,000 revolutions per minute to create the centrifugal forces necessary for isotopic separation 228. Modern European centrifuges typically produce 40-100 SWU per year per machine, while larger American designs can achieve higher individual capacity 2214.

Rows of gas centrifuges inside a uranium enrichment facility, illustrating the vast scale of enrichment capacity.

Enrichment facilities arrange thousands of centrifuges in parallel and series configurations called cascades, with each cascade designed to achieve specific enrichment objectives 2014. A typical commercial enrichment plant may contain 10-20 enrichment stages, compared to over 1,000 stages required for historical gaseous diffusion facilities 814.

Rows of gas centrifuges inside a uranium enrichment facility, illustrating the scale of operations for separative work.

Enrichment Cascade Operations

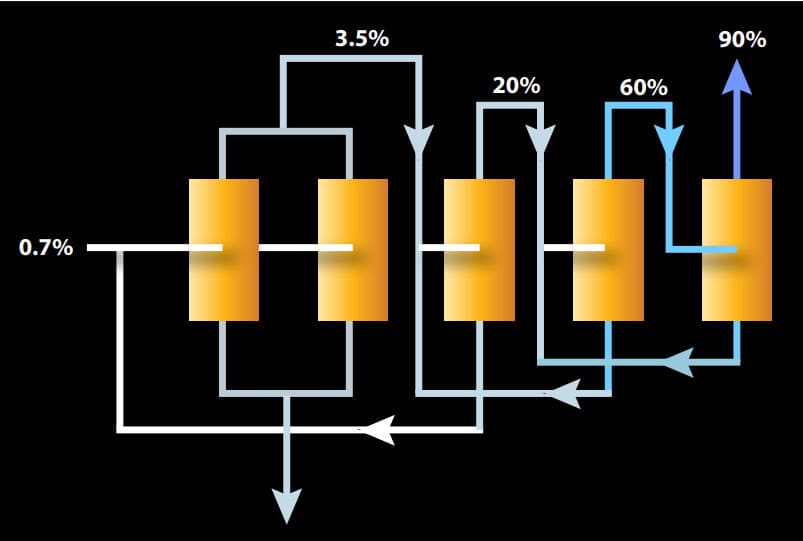

The enrichment cascade concept represents the systematic arrangement of separation stages to achieve desired product specifications while minimizing energy consumption and capital costs 148. Each stage consists of multiple centrifuges operating in parallel, with enriched material feeding forward to subsequent stages and depleted material recycling backward 2014.

Diagram illustrating a multi-stage uranium enrichment cascade, showing the progressive increase in uranium-235 concentration from natural uranium to highly enriched uranium.

Cascade design optimization balances numerous factors including target enrichment levels, feed specifications, tails assay requirements, and economic constraints 1514. Modern cascade facilities can accommodate multiple product streams, allowing simultaneous production of different enrichment levels to serve diverse customer requirements 223.

The continuous operation requirement of gas centrifuges means that enrichment cascades cannot simply be shut down during periods of reduced demand, leading to inventory accumulation and market dynamics unique to the enrichment industry 210. This operational characteristic contributes to periodic oversupply conditions in global enrichment markets 105.

Reactor-Specific SWU Requirements

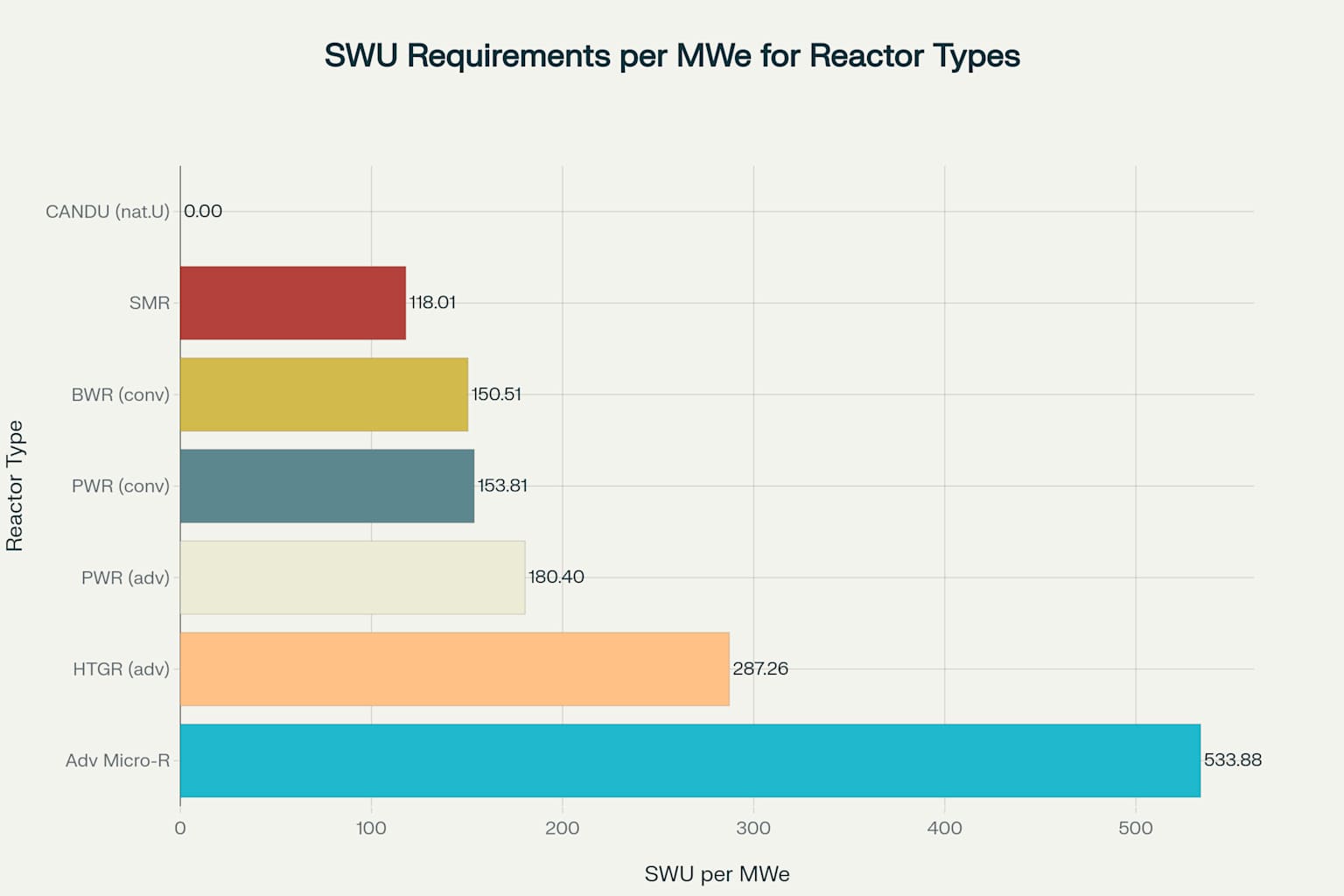

Different reactor technologies exhibit varying SWU requirements based on their fuel specifications, operational characteristics, and design parameters 1819. Conventional light water reactors (PWR and BWR) represent the largest segment of global SWU demand, with typical requirements of 150-180 SWU per megawatt electric per year 1819.

SWU Requirements per MWe for Different Reactor Types

Advanced reactor designs, particularly those utilizing HALEU fuels, demonstrate significantly higher SWU intensity compared to conventional designs 18. Small modular reactors (SMRs) typically require 118 SWU per MWe annually, while high-temperature gas-cooled reactors (HTGR) may need 287 SWU per MWe.

Advanced micro-reactors using 19.5% enriched fuel can require over 500 SWU per MWe annually, reflecting their specialized fuel requirements.

CANDU reactors using natural uranium require zero SWU since they operate without enriched fuel, highlighting the dramatic differences in fuel cycle requirements across reactor technologies 8. These variations have significant implications for enrichment capacity planning as the global reactor fleet evolves toward advanced designs 1819.

Global Enrichment Capacity

World enrichment capacity currently totals approximately 62-70 million SWU annually, dominated by four major suppliers: Rosatom (Russia), CNNC (China), Urenco (Europe/USA), and Orano (France) 62. Russian facilities represent the largest single source of global capacity at over 27 million SWU per year, while Chinese capacity continues expanding rapidly 56.

Recent geopolitical developments have prompted renewed focus on enrichment supply chain security, with European and American utilities seeking alternatives to Russian enrichment services 2425. This shift has accelerated investment in new capacity at existing Western facilities and prompted exploration of additional enrichment plants 2425.

Current global enrichment capacity significantly exceeds immediate demand, creating market pressures that have reduced SWU prices from $160 per SWU in 2010 to approximately $100-110 per SWU in recent years 111. This oversupply situation reflects both reduced nuclear construction rates following the Fukushima accident and continued operation of efficient centrifuge facilities 210.

Economic Market Dynamics

The SWU market operates under unique dynamics driven by the capital-intensive nature of enrichment facilities and the continuous operation requirements of centrifuge technology 210. Long-term contracts dominate the market, with utilities securing enrichment services years in advance to ensure fuel supply security 1211.

Spot market prices for SWU services fluctuate based on supply-demand imbalances, geopolitical factors, and broader nuclear industry trends 1211. The uranium marketing annual report shows average SWU prices ranging from $99-110 per SWU in recent years, with significant variations based on contract terms and delivery schedules 11.

Enrichment economics are closely linked to electricity costs, particularly for facilities using older, less efficient technologies 2. Modern gas centrifuge plants achieve substantial cost advantages through reduced energy consumption, enabling competitive pricing even in oversupplied market conditions 9.

Future Outlook and Advanced Technologies

The future of SWU demand depends heavily on nuclear industry growth prospects and the deployment timeline for advanced reactor technologies 1819. High-assay LEU requirements for next-generation reactors could substantially increase per-unit SWU demand even if total nuclear capacity remains stable 18.

Laser enrichment technologies, particularly the SILEX process under development by Global Laser Enrichment, promise potential improvements in enrichment efficiency and reduced SWU costs 226. These third-generation technologies could offer lower energy inputs, reduced capital costs, and more flexible operation compared to current centrifuge systems 226.

The development of small modular reactors and micro-reactors creates new market segments with distinct SWU requirements, potentially supporting specialized enrichment facilities optimized for HALEU production 1824. These emerging technologies may require enrichment capacity specifically licensed and configured for higher assay levels 2024.

Global enrichment capacity planning must balance uncertain demand projections with long lead times for facility construction and licensing 1819. The strategic nature of enrichment technology ensures continued government involvement in capacity decisions, particularly regarding technology transfer and export controls 221.

The evolution of separative work units from a theoretical concept to a global industrial measurement reflects the sophistication and scale of modern nuclear fuel cycles 15. Understanding SWU provides essential insight into the technical and economic foundations supporting nuclear energy’s continued role in global electricity generation 26.

Footnotes

-

https://en.wikipedia.org/wiki/Separative_work_units ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10 ↩11

-

https://world-nuclear.org/information-library/nuclear-fuel-cycle/conversion-enrichment-and-fabrication/uranium-enrichment ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10 ↩11 ↩12 ↩13 ↩14 ↩15 ↩16 ↩17

-

https://energyeducation.ca/encyclopedia/Separative_work_unit ↩ ↩2 ↩3 ↩4

-

https://scipython.com/blog/uranium-enrichment-and-the-separative-work-unit-swu/ ↩ ↩2 ↩3

-

https://thundersaidenergy.com/downloads/uranium-enrichment-by-country-by-company-by-facility/ ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.worldnuclearreport.org/IMG/pdf/wnisr2023-table17-uranium_enrichment_capacity.pdf ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.eia.gov/energyexplained/nuclear/the-nuclear-fuel-cycle.php ↩

-

https://energyeducation.ca/encyclopedia/Gas_centrifuge_for_uranium_enrichment ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.liquisearch.com/uranium_market/the_swu_separative_work_unit ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

http://web.mit.edu/stgs/pdfs/RothwellBraunEnrichment.pdf ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7

-

https://www.epj-n.org/articles/epjn/full_html/2021/01/epjn210024/epjn210024.html ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7

-

https://fti.neep.wisc.edu/fti.neep.wisc.edu/neep423/FALL99/lecture8.pdf ↩ ↩2 ↩3 ↩4

-

https://ec.europa.eu/eurostat/statistics-explained/index.php/Glossary:Separative_work_unit_(SWU) ↩ ↩2

-

https://programs.fas.org/ssp/nukes/nuclear power and fuel cycle/swu calc.html ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10

-

https://fti.neep.wisc.edu/fti.neep.wisc.edu/neep423/FALL97/lecture7.pdf ↩ ↩2 ↩3

-

https://www.uxc.com/p/cover-stories/uxw_19-41_Neff-Paper.pdf ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7

-

http://wordpress.mrreid.org/2012/08/06/separative-work-units/ ↩ ↩2 ↩3

-

https://apps.dtic.mil/sti/trecms/pdf/AD1152007.pdf ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10

-

https://npolicy.org/wp-content/uploads/2021/09/Estimates-of-Uranium.pdf ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

https://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

https://www.armscontrol.org/act/2014-06/features/agreeing-limits-irans-centrifuge-program-two-stage-strategy ↩ ↩2 ↩3

-

https://coincodex.com/convert/smart-world-union/usd/ ↩ ↩2 ↩3 ↩4

-

https://fissilematerials.org/blog/2024/10/urenco_started_expansion_.html ↩ ↩2

-

https://sgp.fas.org/othergov/doe/lanl/pubs/00416662.pdf ↩ ↩2