Modern centrifuge technology represents one of the most sophisticated engineering achievements in materials science, where extreme mechanical demands meet precise engineering requirements 12. The materials used in centrifuges must withstand incredible forces while maintaining structural integrity over thousands of operational hours 23.

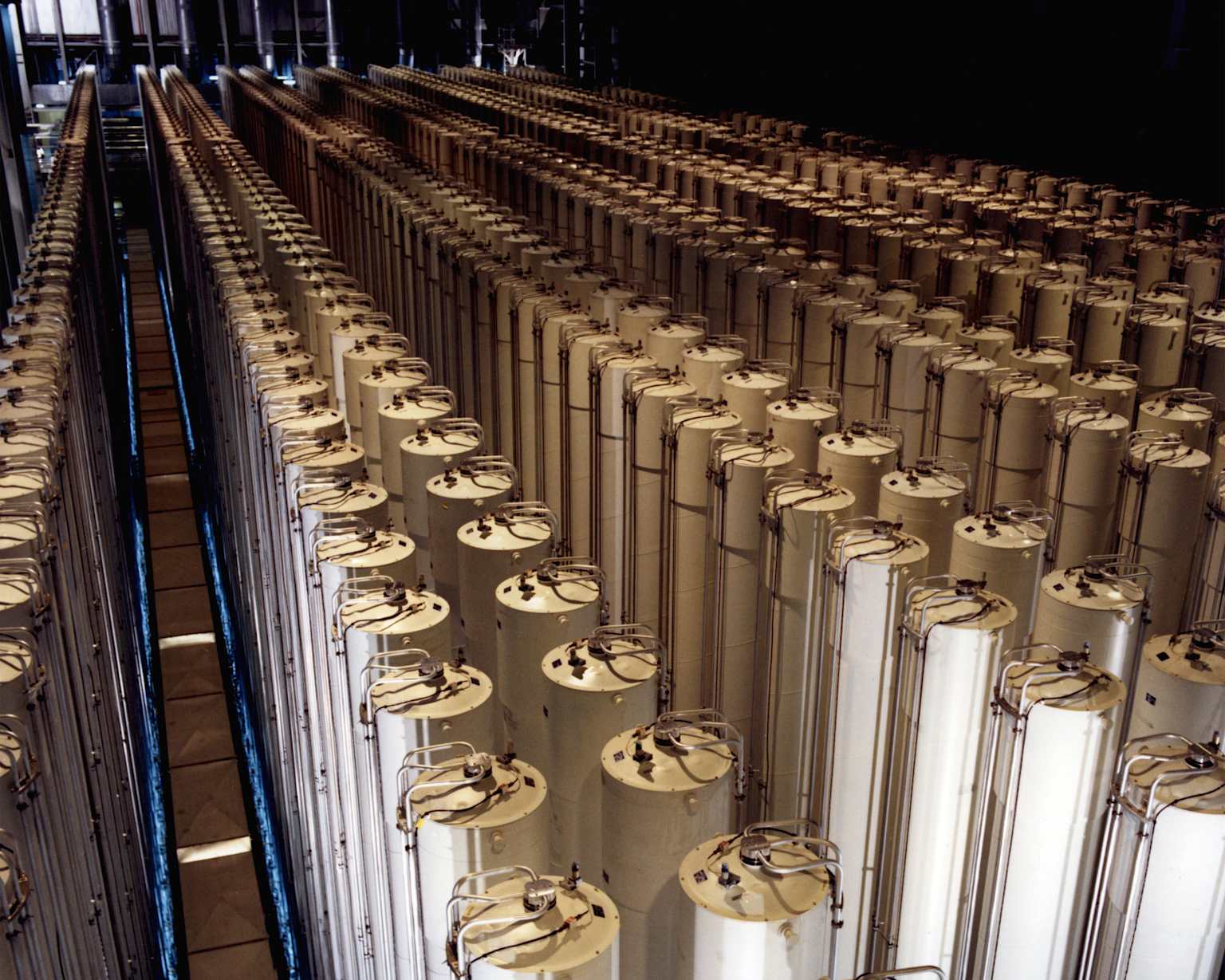

A large industrial facility housing an extensive array of gas centrifuges for uranium enrichment.

Understanding Centrifuge Technology

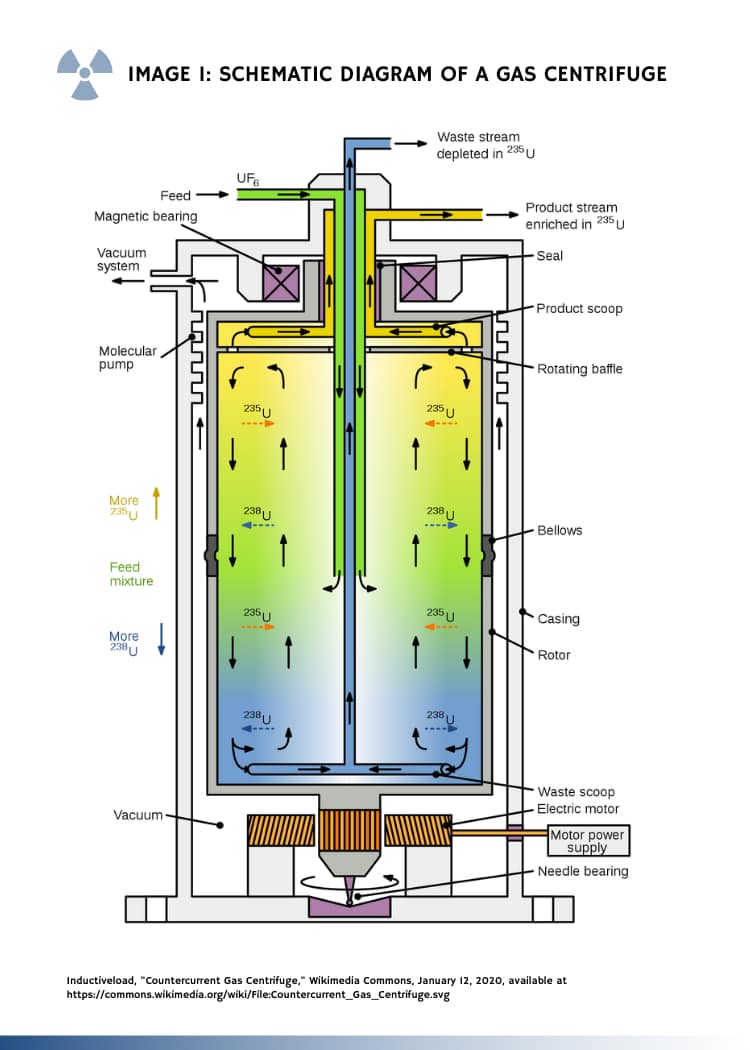

Centrifuges separate materials based on density differences by subjecting them to powerful centrifugal forces 24. These devices range from small laboratory instruments to massive industrial installations used in uranium enrichment facilities 56.

The principle remains consistent across all types: a rotor spins at high speed, generating forces thousands of times greater than gravity, forcing denser materials outward 78. This seemingly simple concept requires extraordinarily sophisticated materials to execute safely and efficiently 69.

Schematic diagram detailing the components and operational flow of a gas centrifuge used for isotope separation.

Material Requirements for Centrifuges

Centrifuge materials must meet several critical requirements to function properly 210. First, they must possess exceptional strength-to-weight ratios to withstand the tremendous forces generated during high-speed rotation 108.

Second, they must resist deformation and fatigue over numerous operational cycles 311. Third, many applications require materials resistant to chemical corrosion or capable of operating in specialized environments 312.

Finally, in specialized applications like gas centrifuges for uranium enrichment, materials must possess dimensional stability and specific magnetic properties 68. These demanding requirements have driven innovations in materials science for decades 119.

Maraging Steel: The Gold Standard

Maraging steel represents one of the most critical materials in high-performance centrifuge design, particularly for uranium enrichment applications 1314. This specialized alloy derives its name from the combination of “martensitic” structure and “aging” heat treatment process 1516.

Unlike conventional steels that rely on carbon for strength, maraging steel contains very low carbon (less than 0.03%) and instead gains its extraordinary properties from precipitation of intermetallic compounds during aging 1517. Key alloying elements include nickel (17-19%), cobalt (8-12%), molybdenum (3-5%), and titanium (0.2-1.6%) 1518.

The manufacturing process involves vacuum induction melting followed by vacuum arc remelting to ensure exceptional purity 1319. After initial shaping, the steel undergoes solution treatment at approximately 820°C followed by cooling to form martensite 2021.

An extensive array of industrial centrifuges in a large-scale enrichment facility.

The critical step comes during aging at 480-500°C for several hours, where nanoscale intermetallic precipitates form, dramatically increasing strength while maintaining toughness 2122. This unique combination of properties makes maraging steel ideal for centrifuge components experiencing extreme stress 1423.

Maraging steel delivers tensile strengths exceeding 2,000 MPa (290,000 psi) while maintaining good toughness and dimensional stability 1724. Its superior resistance to fatigue and creep at high rotational speeds has made it essential for gas centrifuge rotors and bellows 2325.

However, maraging steel isn’t without limitations 2614. It’s expensive to produce and requires specialized manufacturing processes 2620. The material is also subject to export controls due to its applications in nuclear technology 2325.

Carbon Fiber: The Modern Alternative

Carbon fiber composite materials represent a significant advancement in centrifuge technology, offering several advantages over traditional metal alloys 2710. These materials consist of carbon fibers embedded in polymer matrices, creating a lightweight yet incredibly strong material 2811.

Modern centrifuge rotors made from carbon fiber typically contain about 65% carbon fiber embedded in epoxy resin 2728. This construction provides extraordinary strength-to-weight ratios, enabling faster acceleration and deceleration while reducing wear on drive systems 2729.

A PTI FiberLite F10-6x500y centrifuge rotor showcasing its carbon fiber construction with six sample wells.

Carbon fiber rotors weigh approximately 40-60% less than equivalent metal rotors, which translates to safer handling and reduced risk of injury 2730. This weight reduction also allows for higher maximum speeds and significantly shorter total run times 3029.

Beyond weight advantages, carbon fiber offers superior resistance to corrosion, fatigue, and environmental factors 2710. The material also provides natural insulation properties, eliminating the need for pre-cooling steps and helping maintain sample temperature integrity 3132.

One particularly noteworthy advantage is carbon fiber’s ability to withstand repeated stress cycles without developing microcracks that can lead to catastrophic failure in metal rotors 1011. This property has made it the material of choice for advanced centrifuge applications 2933.

A FIBERLite fixed-angle rotor showcasing the distinctive weave pattern of carbon fiber.

In uranium enrichment technology, carbon fiber has become increasingly important 3325. Modern advanced centrifuges like the IR-4, IR-6, and IR-8 models utilize carbon fiber rotors to achieve higher performance metrics 3325.

Despite its advantages, carbon fiber does have limitations 1130. Manufacturing costs remain higher than traditional materials, and production requires specialized techniques like centrifugal infusion to eliminate gas pockets and optimize impregnation 3411.

Aluminum Alloys: The Practical Solution

Aluminum alloys remain among the most widely used materials for centrifuge applications, particularly in laboratory and medical settings 1035. These alloys offer an excellent balance of reasonable cost, good strength, and ease of manufacturing 3637.

The most common aluminum alloys used in centrifuge rotors include 6061 and 7075 grades, which provide good strength-to-weight ratios while maintaining dimensional stability 3738. These materials are particularly suitable for benchtop and superspeed centrifuges where extreme performance isn’t required 1035.

An aluminum alloy centrifuge rotor with 30 places for 15mL tubes, showcasing one of the materials used in centrifuge construction.

Aluminum rotors can be manufactured through various processes, including machining, casting, and forging 3739. The relatively simple manufacturing process helps keep costs lower compared to specialized materials like maraging steel or carbon fiber 3738.

While aluminum doesn’t match the ultimate performance of advanced materials, it offers adequate strength for most laboratory applications while providing excellent corrosion resistance when properly anodized 1238. This makes aluminum ideal for centrifuges handling biological or corrosive samples 3836.

Aluminum alloy rotor designed for a microcentrifuge with twelve sample tube positions.

One notable disadvantage of aluminum is its thermal conductivity characteristics 3132. Aluminum rotors conduct heat rapidly, which can negatively impact temperature-sensitive samples during processing 3231. This contrasts with carbon fiber’s insulating properties 3230.

Titanium: The Specialized Choice

Titanium and its alloys represent another important material category for specialized centrifuge applications 1040. With a density between aluminum and steel, titanium offers an excellent combination of strength, corrosion resistance, and weight savings 4038.

Titanium is particularly valued in ultracentrifuge rotors, which experience the highest stress levels of all centrifuge types 1040. Its greater structural properties compared to aluminum make it suitable for these demanding applications 1038.

The exceptional corrosion resistance of titanium makes it particularly useful in centrifuges handling harsh chemicals or saline environments 4012. This property has made titanium centrifuges common in chemical processing and pharmaceutical applications 4041.

However, titanium’s high cost and complex manufacturing requirements limit its use to specialized applications where its unique properties justify the expense 4042. The material is also more difficult to machine than aluminum, adding to production costs 4238.

Material Selection Criteria

Engineers selecting materials for centrifuge applications must consider numerous factors beyond simple mechanical properties 3843. The application requirements, operating environment, and cost constraints all play crucial roles in material selection 4311.

For laboratory centrifuges, considerations include chemical compatibility with samples, ease of cleaning, and autoclavability 4443. These requirements often favor materials like anodized aluminum or specialized polymers for tube holders 4344.

For industrial centrifuges, factors like wear resistance, maintenance requirements, and expected service life become paramount 345. These applications may require specialized stainless steels or corrosion-resistant coatings 312.

In uranium enrichment centrifuges, the primary considerations include maximum achievable rotation speed, dimensional stability, and resistance to the corrosive effects of uranium hexafluoride gas 68. These demanding requirements have driven the adoption of maraging steel and carbon fiber 833.

Future Trends in Centrifuge Materials

The future of centrifuge materials points toward continued innovation in composite materials and specialized alloys 4647. Advanced carbon fiber composites with improved matrix materials show promise for higher performance and longer service life 4648.

Nanomaterials are beginning to play a role in next-generation centrifuges, offering potential improvements in strength, durability, and functionality 4648. These materials could enable even higher rotational speeds while maintaining safety margins 4849.

Hybrid materials combining the properties of different material classes represent another promising direction 5049. These materials aim to capture the best characteristics of metals, composites, and ceramics in a single material system 5046.

Additive manufacturing techniques are increasingly being applied to centrifuge component production, allowing for previously impossible geometric designs that optimize material distribution 4749. This approach could lead to more efficient centrifuge designs with improved performance characteristics 4748.

Conclusion

The materials used in centrifuge construction represent a fascinating intersection of materials science, mechanical engineering, and application-specific requirements 12. From the extraordinary strength of maraging steel to the lightweight advantages of carbon fiber and the practical benefits of aluminum alloys, each material offers distinct advantages for particular applications 101527.

As centrifuge technology continues to advance, materials will remain a critical factor determining performance limits, operational safety, and economic feasibility 1146. Engineers must carefully balance these considerations when selecting materials for specific centrifuge applications 4338.

The evolution of centrifuge materials illustrates how specialized engineering challenges drive innovation in materials science 1046. This continuous development process ensures that centrifuge technology will continue to advance, enabling new applications and improved performance across scientific, medical, and industrial domains 4648.

Footnotes

-

https://www.hawach.com/news/material-and-use-of-centrifuge-tube.html ↩ ↩2

-

https://www.flottweg.com/engineering/decanter-features/materials/ ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html ↩

-

https://world-nuclear.org/information-library/nuclear-fuel-cycle/conversion-enrichment-and-fabrication/uranium-enrichment ↩ ↩2 ↩3 ↩4

-

https://visionias.in/current-affairs/upsc-daily-news-summary/article/2025-03-31/the-hindu/science-and-technology/centrifuge-getting-to-the-good-uranium ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.scitechnol.com/peer-review/gas-centrifuge-an-important-technology-for-uranium-enrichment-g5mv.php?article_id=26052 ↩ ↩2

-

https://www.americanlaboratory.com/913-Technical-Articles/1046-Centrifuge-Rotor-Material-Evolution-Advances-in-Rotor-Design-Using-Composite-Materials/ ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10 ↩11 ↩12

-

http://apps.thermoscientific.com/media/LPG/PDF/ABLCentrifugeRotor.pdf ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8

-

https://dolphincentrifuge.com/stainless-steel-centrifuge/ ↩ ↩2 ↩3 ↩4

-

https://www.lintsteels.com/blog/what-is-maraging-steel-used-for/ ↩ ↩2 ↩3

-

https://www.mststeel.com/maraging-steel-unique-properties-uses/ ↩

-

https://steelprogroup.com/alloy-steel/maraging-steel-guide/ ↩ ↩2

-

https://data.epo.org/publication-server/rest/v1.0/publication-dates/20170524/patents/EP3170911NWA1/document.pdf ↩

-

https://www.repository.cam.ac.uk/items/d37614d7-3b41-4835-b524-44b21df4ff9f ↩ ↩2

-

https://www.dierk-raabe.com/martensite-alloys-and-transformations/maraging-trip-steels/ ↩

-

https://isis-online.org/isis-reports/detail/further-indications-of-irans-renewed-interest-in-maraging-steel/8 ↩ ↩2 ↩3

-

https://isis-online.org/isis-reports/detail/september-2022-highlights-of-survey-of-irans-advanced-centrifuges/8 ↩ ↩2 ↩3 ↩4

-

https://blog.thepipingmart.com/metals/advantages-and-disadvantages-of-maraging-steel/ ↩ ↩2

-

https://www.avantorsciences.com/pr/en/product/4832466/fiberlitetm-centrifuge-rotors-thermo-scientific ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

https://tools.thermofisher.com/content/sfs/brochures/D21232~.pdf ↩ ↩2

-

http://assets.thermofisher.com/TFS-Assets/LPD/Reference-Materials/lpd-gps-five-reasons-fiberlite-rotors-brochure.pdf ↩ ↩2 ↩3

-

https://assets.fishersci.com/TFS-Assets/LPD/brochures/fiberlite-brochure-BRCFGFLROTSOL0818.pdf ↩ ↩2 ↩3 ↩4

-

https://assets.thermofisher.com/TFS-Assets/LED/Specification-Sheets/D20861~.pdf ↩ ↩2 ↩3

-

https://assets.thermofisher.com/TFS-Assets/LPD/Application-Notes/fiberlite-rotors-smart-note.pdf ↩ ↩2 ↩3 ↩4

-

https://www.iranwatch.org/our-publications/weapon-program-background-report/irans-centrifuges-models-status ↩ ↩2 ↩3 ↩4

-

https://www.labrepco.com/product/aluminum-alloy-rotor-for-d3024-d3024r-micro-centrifuges-holds-24-x-1-5-2-0ml-centrifuge-tubes/ ↩ ↩2

-

https://www.bsilab.com/product/aluminum-alloy-rotor-for-d3024-d3024r-micro-centrifuge-holds-36-x-0-5ml-centrifuge-tubes/ ↩ ↩2

-

https://www.johnsoncentrifugal.com/blog/comparing-356-vs-6061-aluminum-alloy ↩ ↩2 ↩3 ↩4

-

https://newlifescientific.com/collections/rotors ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9

-

https://www.alibaba.com/showroom/titanium-centrifuge.html ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

https://de.scribd.com/document/650311488/Centrifuges-for-Industrial-Minerals-Gea-Tcm11-29030 ↩

-

https://www.mini-plast.com/considerations-when-choosing-centrifuge-tubes/ ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.hawachlab.com/news/differences-between-plastic-and-glass-centrifuge-tube/ ↩ ↩2

-

https://www.huadacentrifuge.com/news-analysis-of-common-failure-causes-of-operating-centrifuges.html ↩

-

https://www.gmi-inc.com/the-future-of-ultra-centrifugation-predictions-and-trends/ ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7

-

https://www.drawellanalytical.com/exploring-advanced-rotor-designs-of-floor-centrifuges/ ↩ ↩2 ↩3

-

https://www.marketresearchintellect.com/blog/revolutionizing-technology-the-surge-of-next-generation-centrifuges/ ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.cencelab.com/advancements-in-rotor-design-for-automated-centrifuge.html ↩ ↩2 ↩3

-

https://www.processindustryinformer.com/hybrid-centrifuge-liquid-liquid-separator/ ↩ ↩2