The Challenge of Uranium Enrichment

Uranium enrichment represents one of the most complex industrial processes in the world, requiring both technological precision and massive scale to achieve results 1. At its core, the process aims to increase the concentration of the rare uranium-235 isotope from its natural level of about 0.7% to the 3-5% needed for nuclear power plant fuel 2.

The fundamental challenge lies in the tiny mass difference between uranium isotopes – uranium-235 is only about 1% lighter than uranium-238 3. This minimal difference makes separation extremely difficult, requiring specialized equipment and sophisticated arrangements to achieve meaningful enrichment 4.

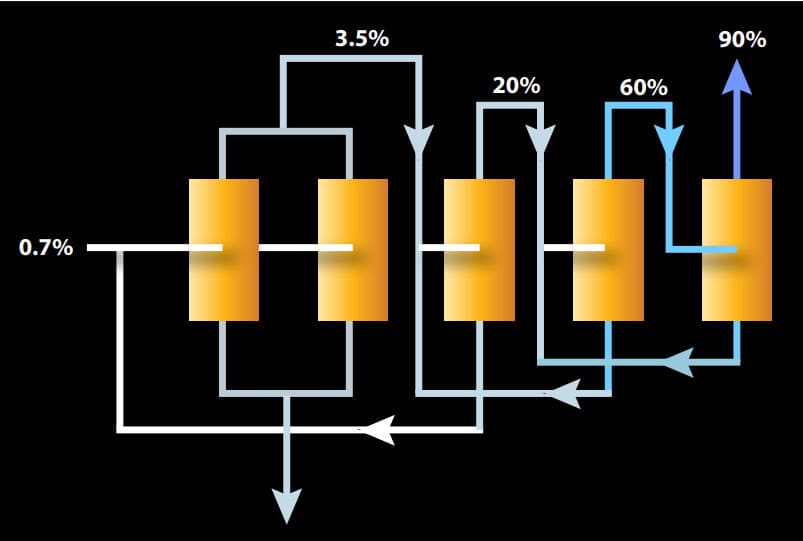

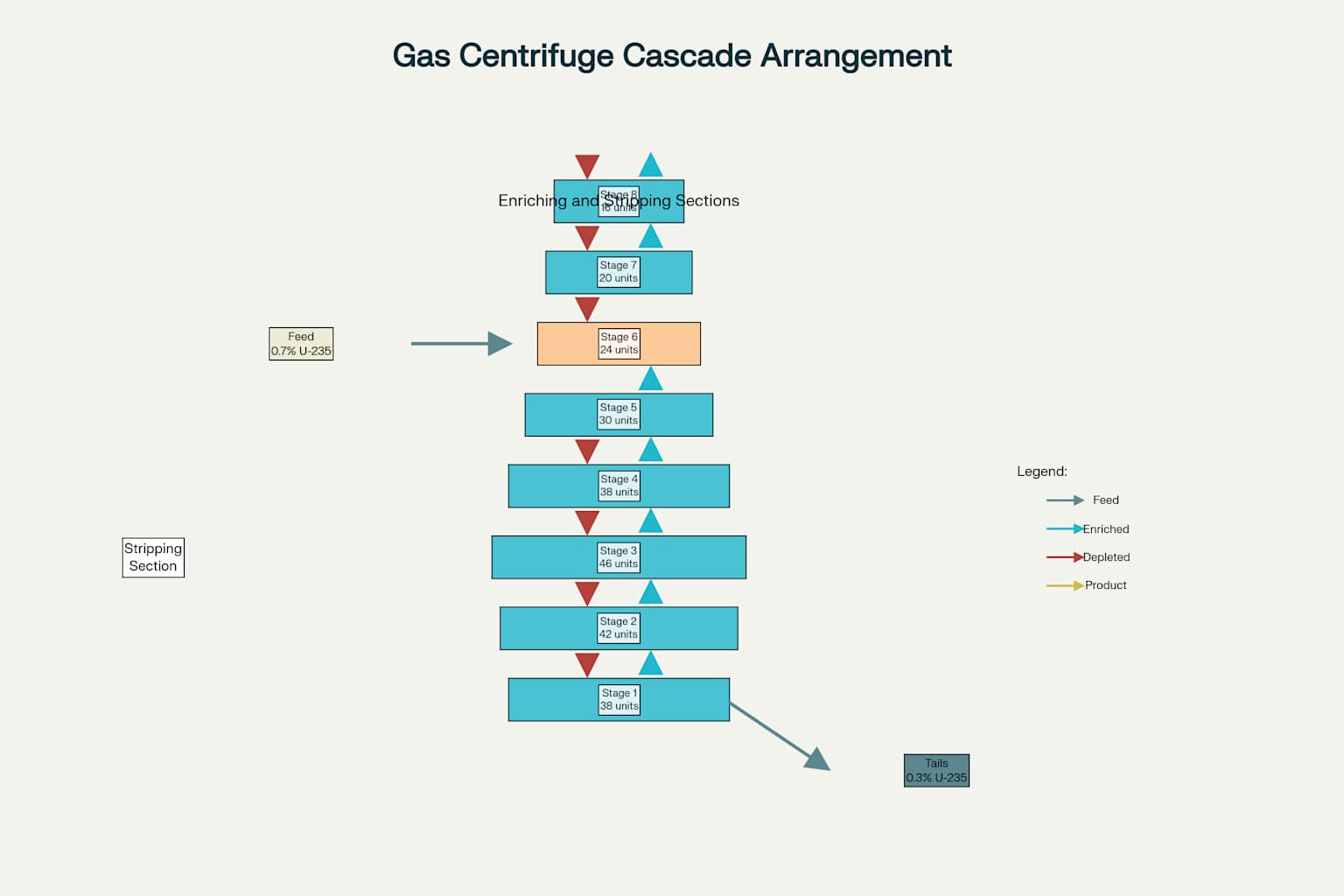

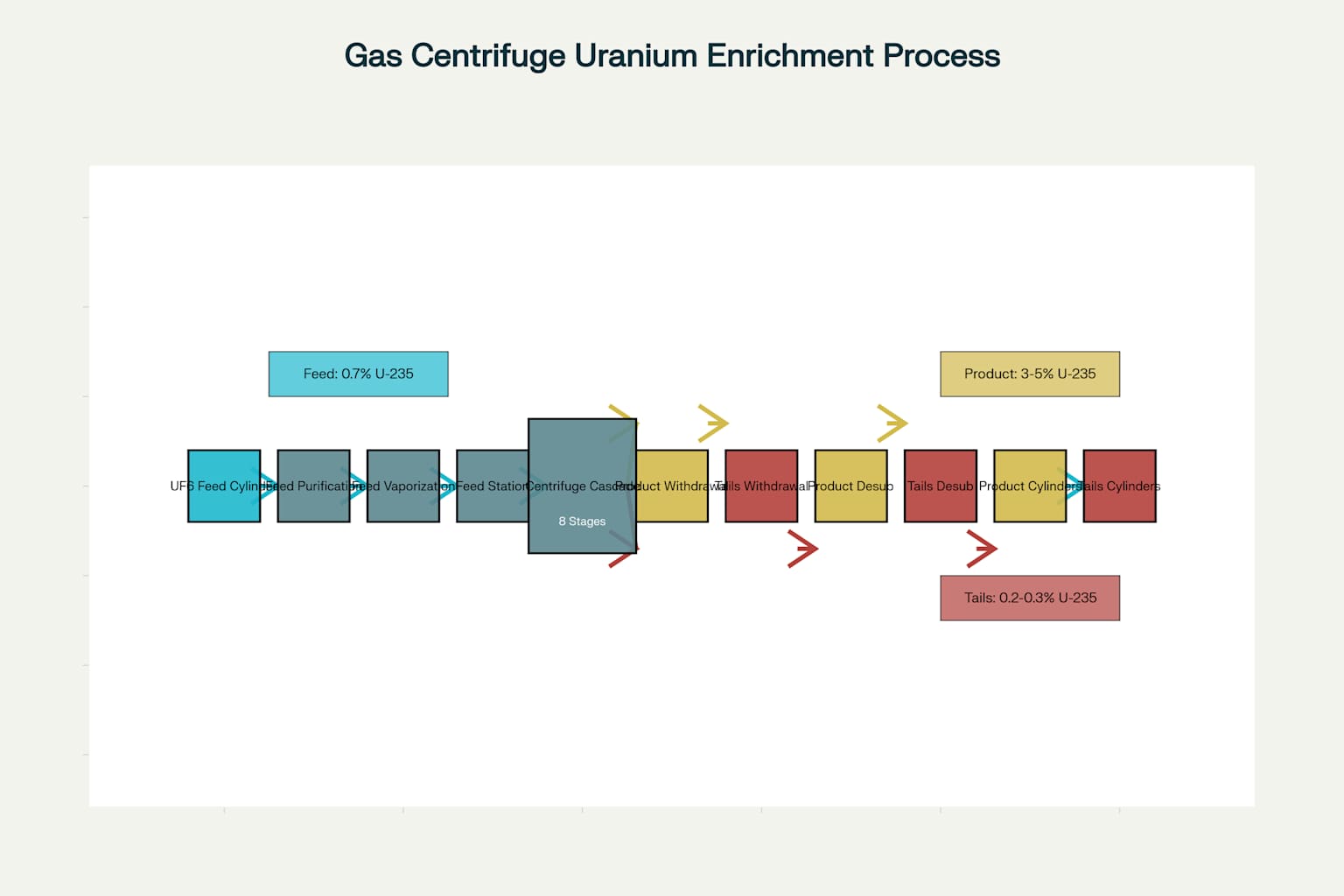

Simplified diagram of a multi-stage uranium enrichment cascade, illustrating the progressive increase in U-235 concentration from natural uranium to highly enriched uranium.

The Gas Centrifuge: The Building Block

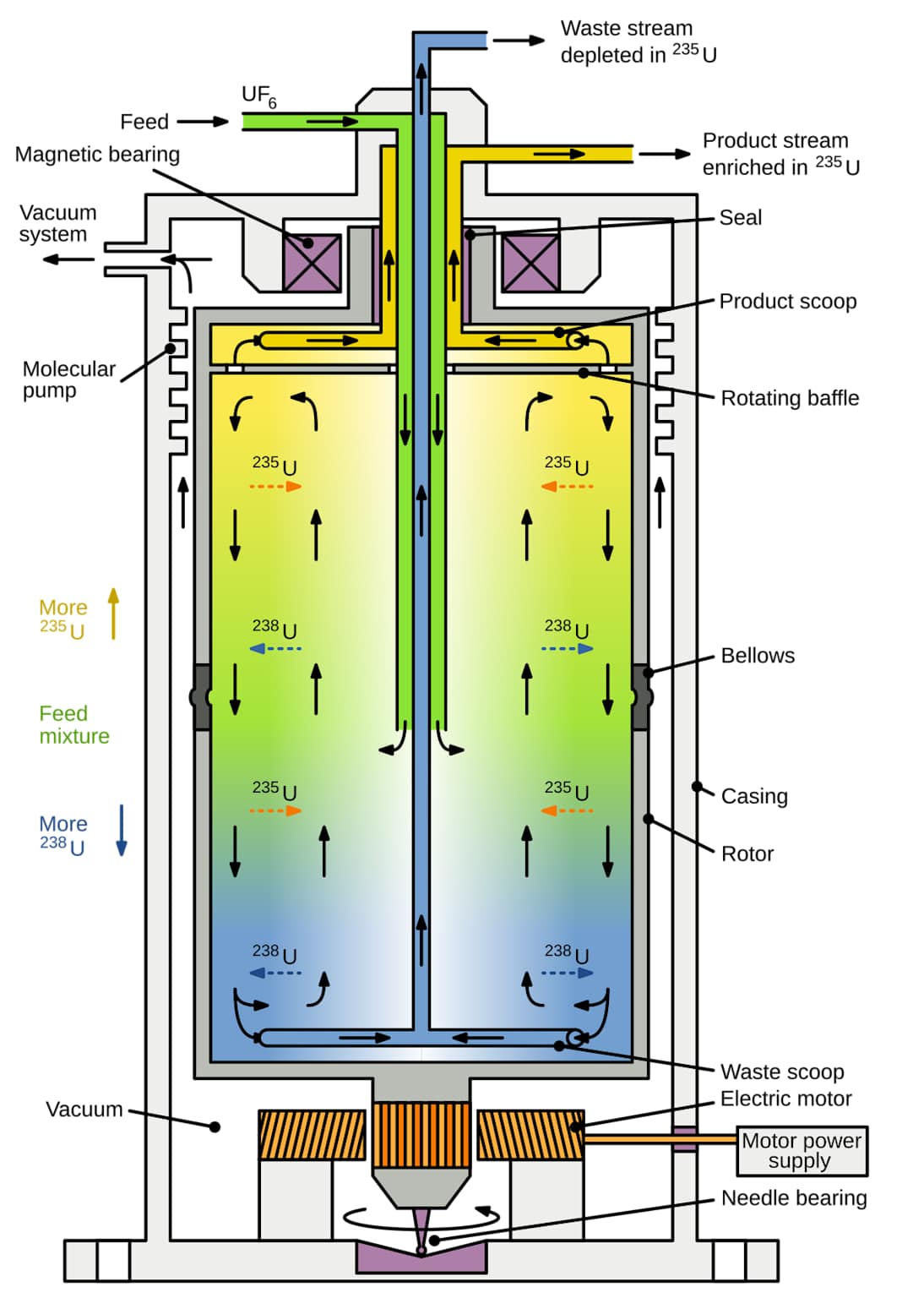

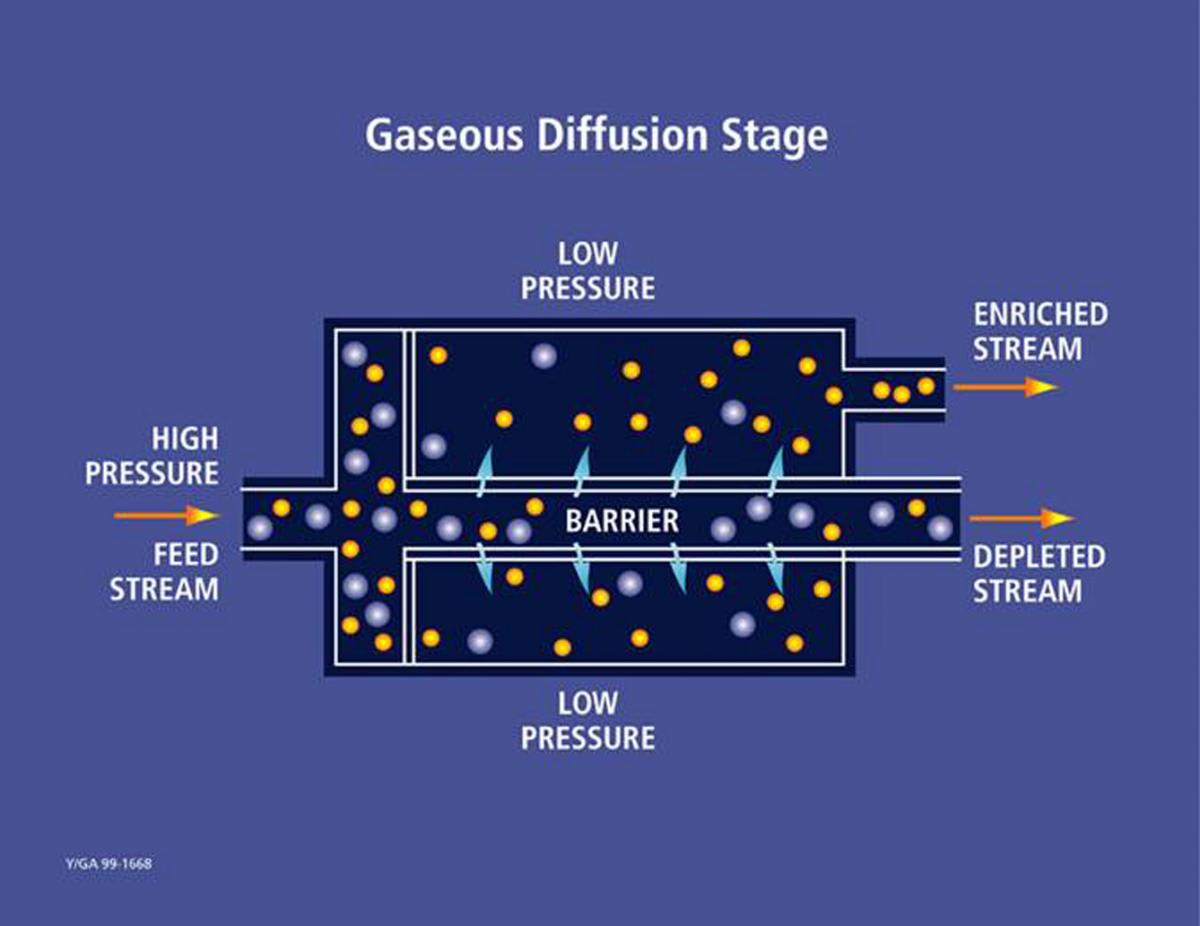

The gas centrifuge has emerged as the dominant technology for uranium enrichment worldwide, replacing older gaseous diffusion methods due to its greater efficiency 5. Each centrifuge is essentially a precision-engineered spinning cylinder that exploits centrifugal force to separate isotopes 2.

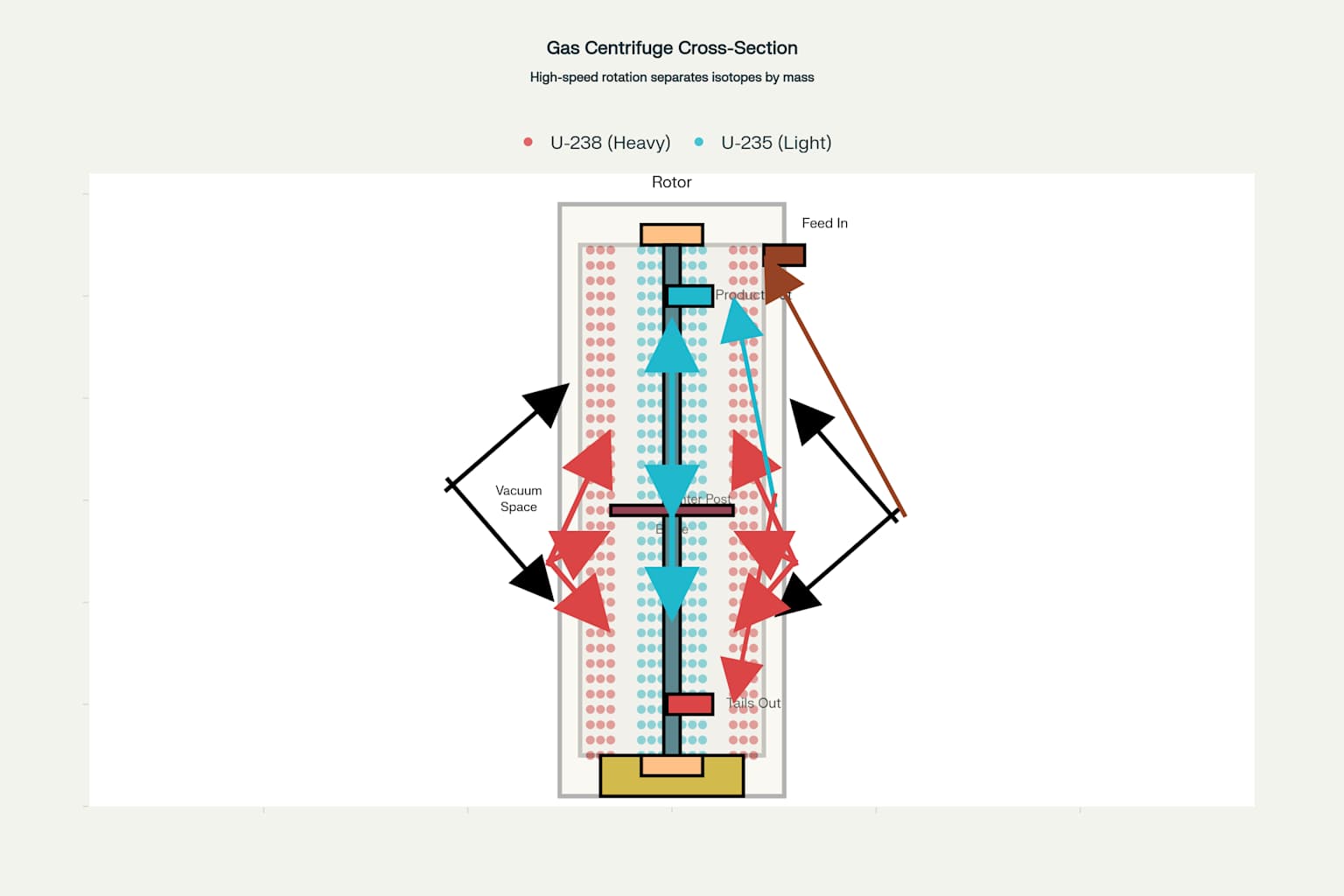

Inside a gas centrifuge, uranium hexafluoride (UF6) gas is fed into a rapidly rotating cylinder 6. The heavier U-238 molecules are pushed toward the outer walls, while the lighter U-235 molecules concentrate toward the center 7. This creates a small but crucial separation effect that forms the basis of the enrichment process 8.

The centrifuge’s rotor spins at incredible speeds – typically around 50,000 to 70,000 RPM – creating forces thousands of times stronger than gravity 9. This high-speed rotation, combined with a countercurrent flow within the cylinder, maximizes the separation of isotopes 10.

Diagram illustrating the internal components and uranium isotope separation process within a gas centrifuge.

Key Components of a Gas Centrifuge

Each gas centrifuge contains several critical components that work in harmony 11. The thin-walled rotor, typically made from high-strength materials like aluminum alloys, maraging steel, or carbon fiber composites, forms the heart of the machine 12.

The centrifuge includes a stationary center post through which the UF6 gas enters and exits 13. Special scoops extend from this post to withdraw the separated streams – enriched product from near the center and depleted tails from near the walls 14.

The entire assembly requires sophisticated bearings at both ends to support the high-speed rotation, along with motors, vacuum systems, and protective casings 15. Each component must function perfectly to maintain operation, as any imbalance can cause catastrophic failure 16.

Cross-Section of a Gas Centrifuge for Uranium Enrichment

Why Cascades Are Essential

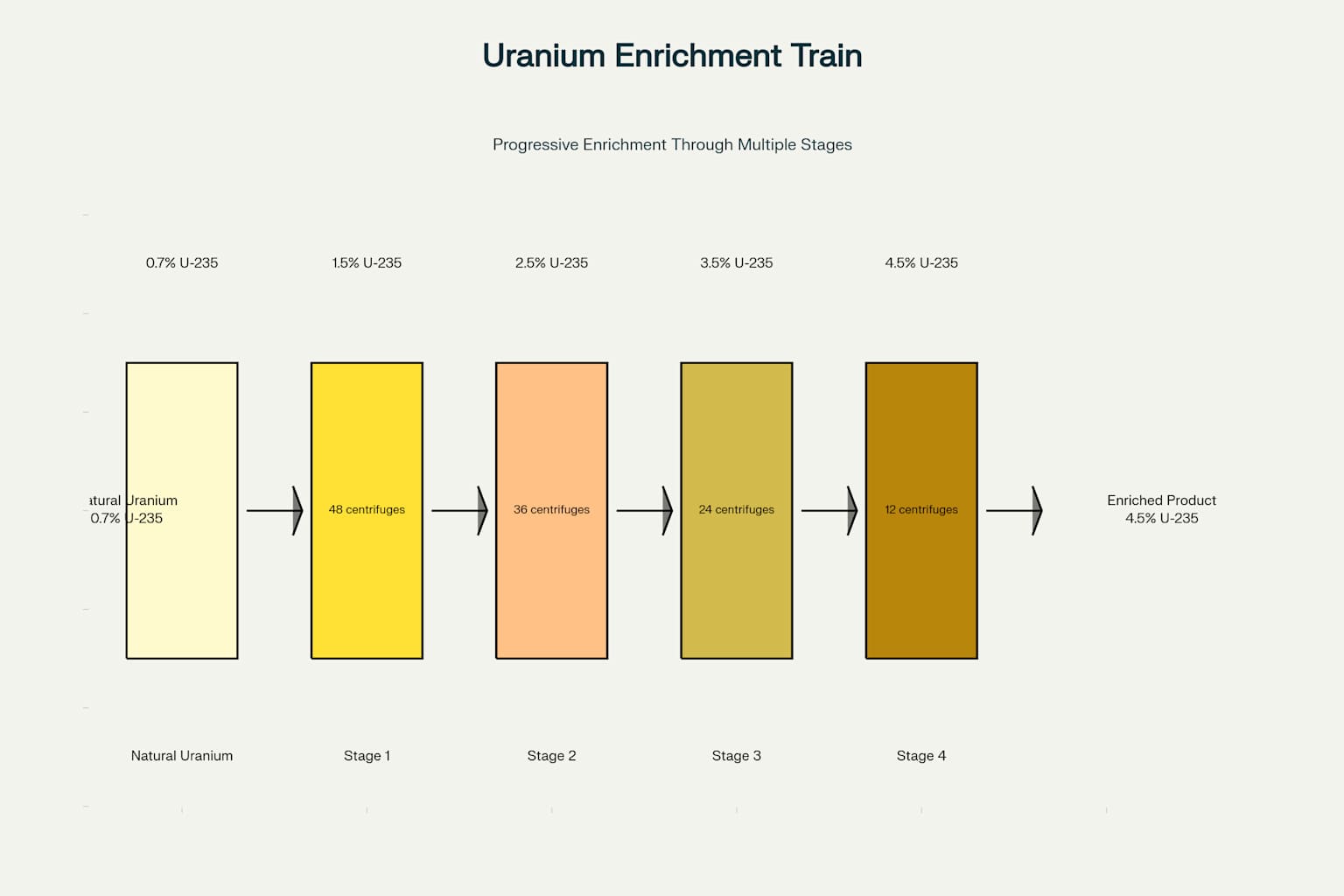

A single gas centrifuge, despite its technological sophistication, produces only a tiny enrichment effect 3. Each machine can only increase the U-235 concentration by a small fraction – typically achieving a separation factor of about 1.05 to 1.2 17.

To reach the 3-5% enrichment needed for reactor fuel, the process must be repeated multiple times 18. This is where the concept of “cascades” becomes essential – arranging centrifuges in specific configurations to progressively enrich uranium through multiple stages 19.

The cascade arrangement enables the small separation effect of individual centrifuges to be multiplied, gradually building up the concentration of U-235 to useful levels 20. Without this arrangement, uranium enrichment at industrial scale would be practically impossible 21.

Uranium Enrichment Train Showing Progressive Concentration of U-235

The Cascade Arrangement: Stages and Sections

A centrifuge cascade consists of multiple “stages,” with each stage containing centrifuges arranged in parallel 3. These stages are then connected in series to form the complete cascade, allowing for progressive enrichment 22.

Cascades typically have two main sections: an “enriching section” where the U-235 concentration increases toward the desired product level, and a “stripping section” where the maximum amount of U-235 is extracted from the depleted stream 23. This design maximizes efficiency and recovery of the valuable U-235 isotope 24.

The size and shape of each cascade is carefully optimized based on mathematical models 25. An “ideal cascade” represents the theoretically most efficient arrangement, though practical limitations mean actual cascades approximate this ideal 26.

Gas Centrifuge Cascade Arrangement in Uranium Enrichment

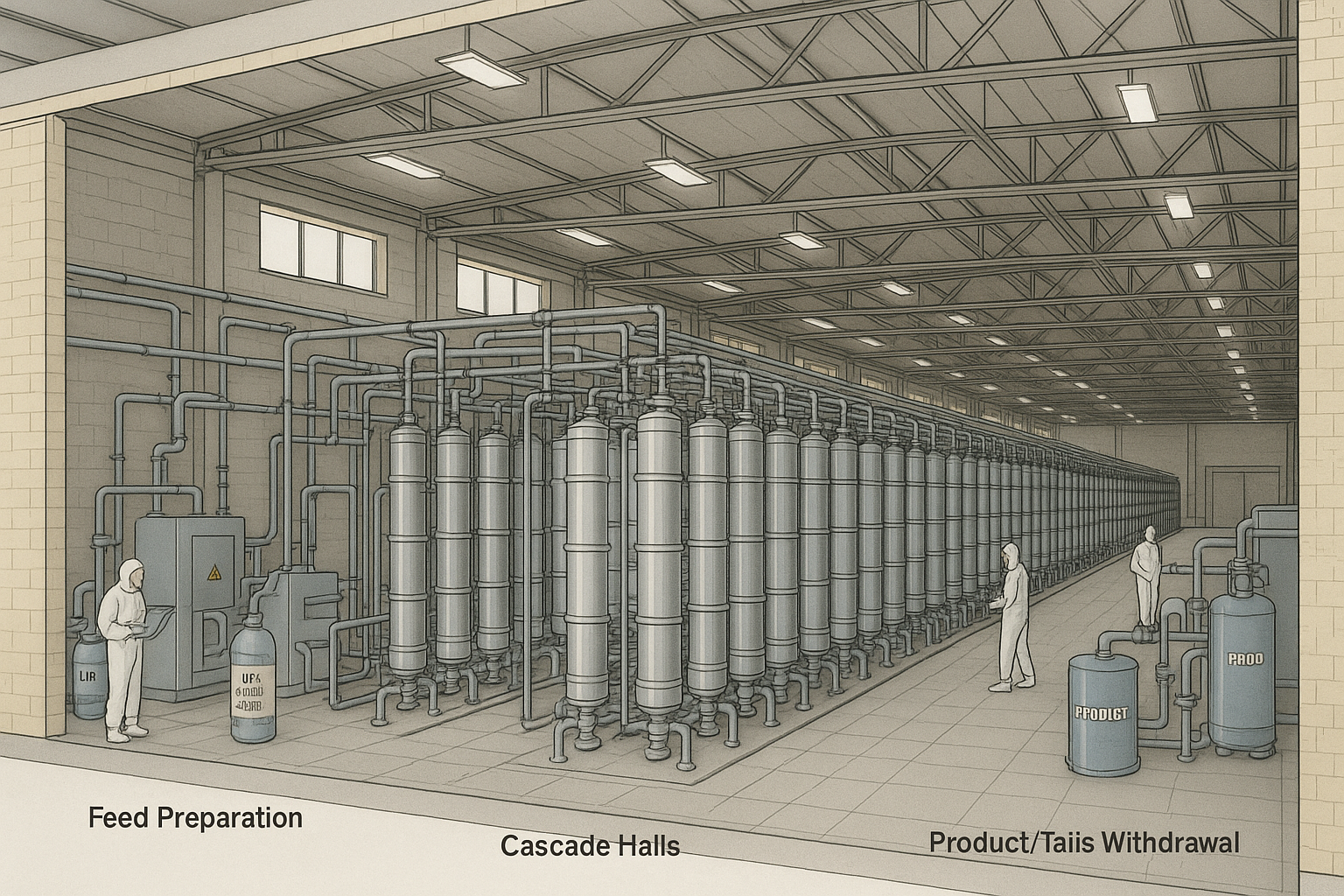

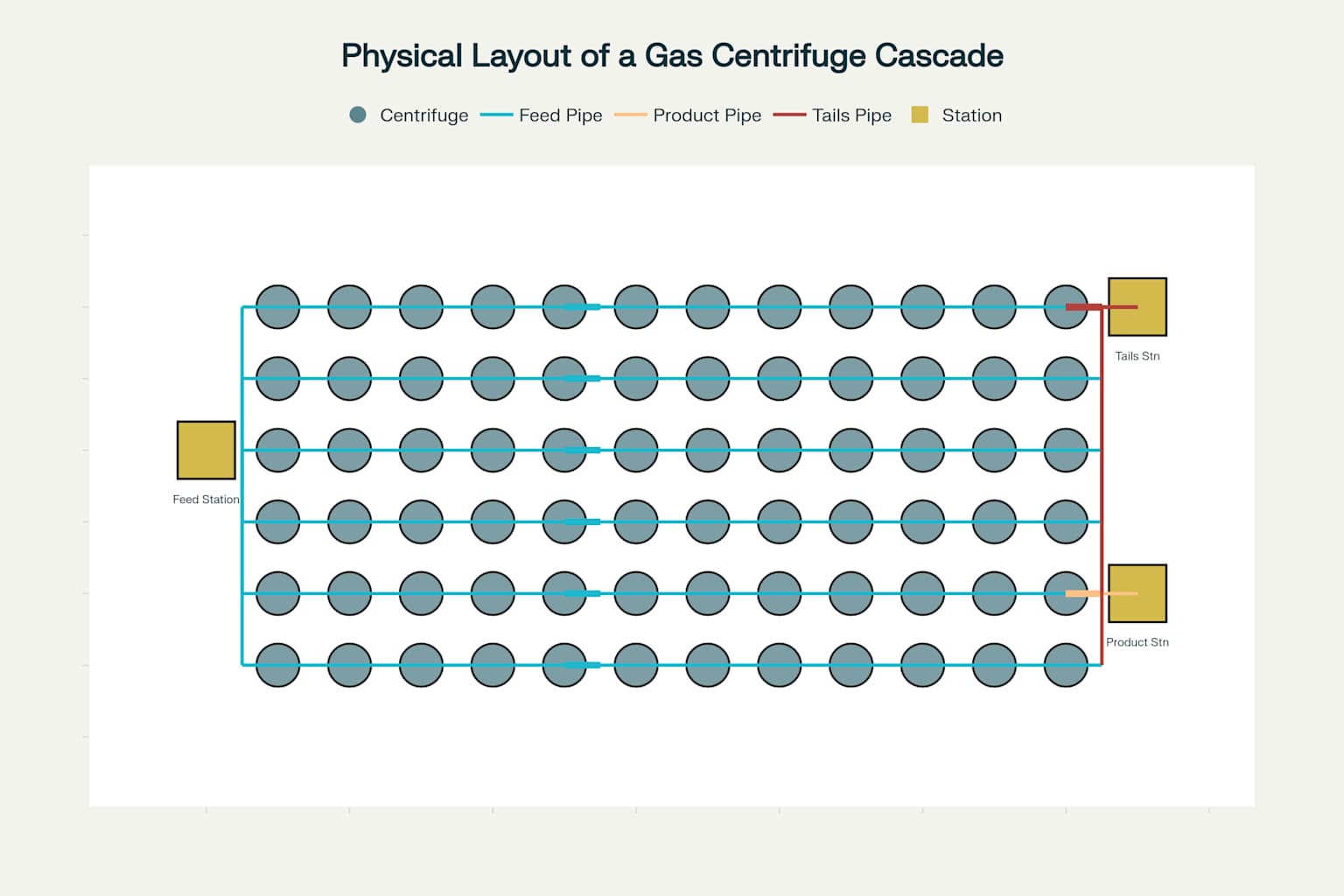

Physical Layout of Centrifuge Facilities

Modern enrichment facilities contain thousands of centrifuges arranged in long rows within large, specially-designed buildings 4. These buildings, often called cascade halls, house the precisely arranged machines in a controlled environment 27.

The centrifuges are mounted on concrete foundations and connected by an intricate network of piping that carries the UF6 gas between stages 28. The entire system requires careful pressure balancing and flow control to maintain proper operation 29.

Enrichment facilities also include support systems for feed and withdrawal of material, sampling stations, control rooms, cooling systems, and backup power supplies 30. Everything is designed to ensure continuous, reliable operation of the delicate enrichment process .

Cutaway illustration of a modern uranium enrichment facility showing multiple centrifuge cascades arranged in parallel halls

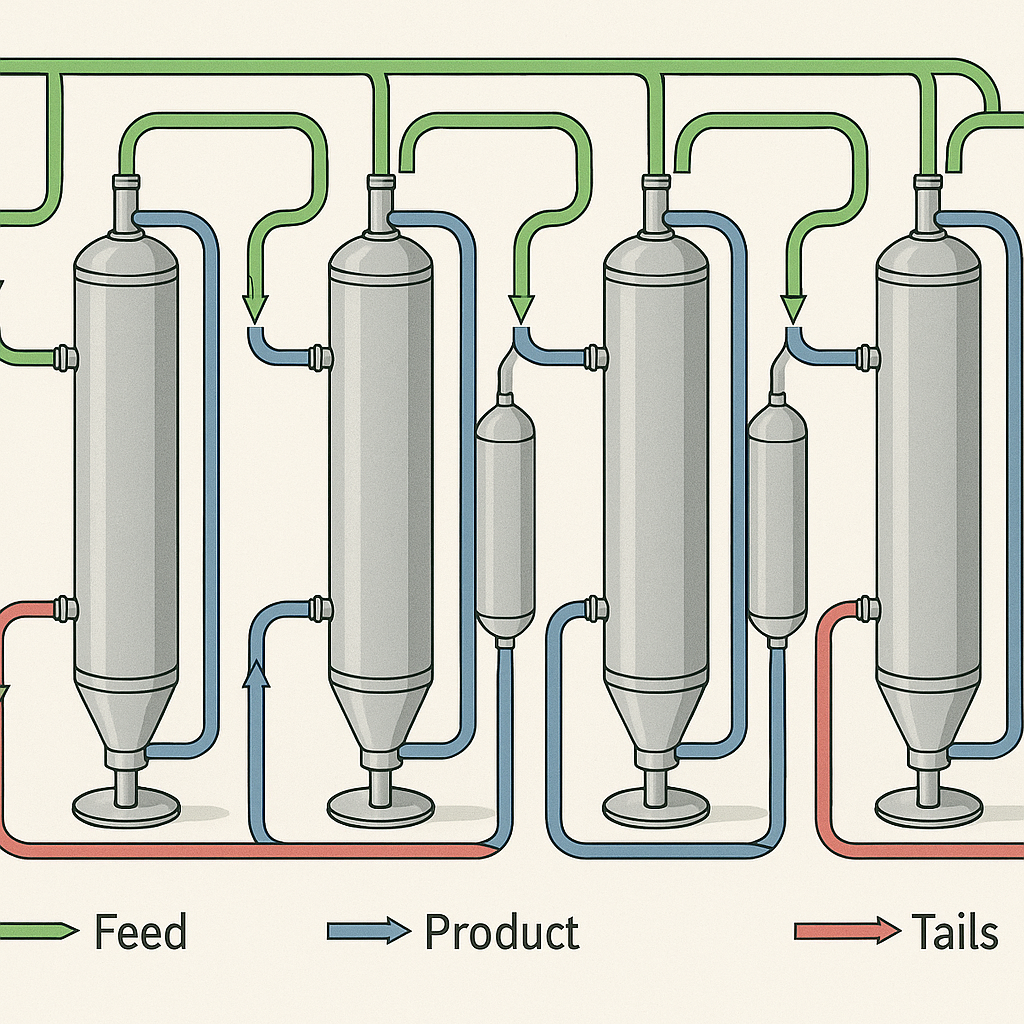

How Centrifuges Connect: The Piping Network

The interconnection of centrifuges within a cascade involves a sophisticated piping system . Three main types of pipes connect the machines: feed pipes bringing UF6 into each centrifuge, product pipes carrying enriched material to the next stage, and tails pipes returning depleted material to previous stages .

Header pipes connect groups of centrifuges in parallel, allowing them to function as a single stage . Special valves control the flow rates between stages, ensuring the optimal operation of the entire cascade .

This piping network must be perfectly balanced to maintain proper pressures and flows throughout the cascade . Even small imbalances can reduce efficiency or potentially cause failures in the sensitive centrifuge machines .

Close-up technical illustration of uranium centrifuges showing the interconnecting piping system in a cascade

The Enrichment Train Concept

An “enrichment train” refers to the sequential path that uranium follows as it progressively increases in U-235 concentration through multiple stages . The term evokes the image of a train moving through stations, with each station representing an enrichment stage .

As uranium moves through the enrichment train, its U-235 concentration increases in a step-wise fashion from the natural 0.7% to the final desired enrichment level . Each stage in the train typically achieves a specific intermediate enrichment level .

Modern enrichment facilities may contain multiple parallel enrichment trains, each consisting of several cascade arrangements . This provides both redundancy and flexibility in operation, allowing for maintenance of some sections while others continue to operate .

Physical Layout of a Gas Centrifuge Cascade Hall

The Complete Enrichment Process

The enrichment process begins with the delivery of uranium hexafluoride in solid form within specialized cylinders . This material is heated to create a gas and purified before entering the cascade system .

The gaseous UF6 passes through the enrichment cascade, where the concentration of U-235 is progressively increased . After reaching the desired enrichment level, the product is withdrawn and collected in cooling chambers where it solidifies .

The entire process requires precise control of temperatures, pressures, and flow rates to maintain efficient operation . Any disruptions can affect not just productivity but potentially create safety concerns given the corrosive nature of UF6 .

Gas Centrifuge Uranium Enrichment Process Flow

Engineering Challenges of Cascade Systems

Creating and maintaining effective centrifuge cascades presents numerous engineering challenges . The extremely high rotational speeds of centrifuges create significant mechanical stresses that must be managed through precise manufacturing and materials selection .

Each centrifuge must be perfectly balanced and supported to prevent vibrations that could lead to catastrophic failures 8. The bearings, motors, and control systems must function flawlessly for years without interruption .

The interconnection of thousands of centrifuges requires meticulous planning and execution 4. The entire system must be designed to isolate any failures that occur, preventing a single machine failure from cascading into widespread damage .

A large array of tall gas centrifuges configured in a cascade for uranium enrichment within an industrial facility.

The Evolution of Centrifuge Technology

Centrifuge technology has evolved significantly since its initial development . Early centrifuges were relatively simple and inefficient, while modern machines incorporate advanced materials and sophisticated design features .

The progression from first-generation to current centrifuges has seen dramatic improvements in separation efficiency, reliability, and energy consumption . Modern centrifuges can operate for many years with minimal maintenance, a crucial factor when thousands are deployed in a facility .

Research continues on next-generation centrifuge designs that promise even greater efficiency and lower operating costs . These advances help make nuclear power more economically competitive while maintaining strict non-proliferation standards .

Efficiency and Scale of Modern Facilities

Modern centrifuge enrichment plants represent remarkable achievements in industrial scale and efficiency . A typical commercial facility might contain 10,000 to 50,000 individual centrifuges arranged in multiple cascade halls 2.

Despite their massive scale, these facilities use relatively little electricity compared to older enrichment technologies . Gas centrifuge plants consume approximately 50 kWh per separative work unit (SWU), compared to about 2,500 kWh for the older gaseous diffusion process .

This efficiency translates to lower operating costs and reduced environmental impact . The modular nature of centrifuge cascades also allows for incremental capacity expansion as demand increases .

Diagram illustrating a single stage of the gaseous diffusion process, showing the separation of a feed stream into enriched and depleted outputs.

Conclusion: The Symphony of Thousands

Centrifuge cascades represent one of humanity’s most impressive technical achievements – thousands of precision machines working in perfect harmony to accomplish what would be impossible individually . The concept elegantly solves the fundamental challenge of uranium enrichment by multiplying the tiny separation effect of single machines into industrially useful output .

Understanding how these cascades function provides insight into both the technical challenges and the ingenious solutions developed for nuclear fuel production . The arrangement of centrifuges in cascades and trains demonstrates how careful engineering can transform theoretical concepts into practical industrial processes .

As energy demands grow worldwide, these sophisticated enrichment systems will continue to play a vital role in providing the fuel needed for carbon-free nuclear power generation . The centrifuge cascade stands as a testament to what can be achieved when engineering precision is applied at massive scale .

Footnotes

-

https://world-nuclear.org/information-library/nuclear-fuel-cycle/conversion-enrichment-and-fabrication/uranium-enrichment ↩ ↩2 ↩3

-

https://programs.fas.org/ssp/nukes/fuelcycle/centrifuges/cascades.html ↩ ↩2 ↩3

-

https://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html ↩ ↩2 ↩3

-

https://resources.inmm.org/annual-meeting-proceedings/gas-centrifuge-cascade-study-maximum-assays-during-start ↩

-

https://pubs.aip.org/physicstoday/article/61/9/40/413428/The-gas-centrifuge-and-nuclear-weapons ↩

-

https://armscontrolcenter.org/uranium-enrichment-for-peace-or-for-weapons/ ↩ ↩2

-

https://www.armscontrol.org/act/2014-06/features/agreeing-limits-irans-centrifuge-program-two-stage-strategy ↩

-

https://programs.fas.org/ssp/nukes/nuclear power and fuel cycle/centrifugesimulator.html ↩

-

https://www.osti.gov/opennet/manhattan-project-history/Processes/UraniumSeparation/centrifuges.html ↩

-

https://isis-online.org/uploads/conferences/audio-video/separative_work_October_30_2014_-_5-2.pdf ↩

-

https://isis-online.org/uploads/conferences/audio-video/Gas_centrifuges_nov_6_2014_-_6_-2.pdf ↩

-

https://escholarship.org/content/qt3vk1w9sf/qt3vk1w9sf.pdf?t=s9xco7 ↩

-

https://www.hellenicaworld.com/Science/Physics/en/GasCentrifuge.html ↩

-

https://isis-online.org/uploads/isis-reports/documents/WCWitt__Modeling_Irans_Tandem_Cascade_Configuration_for_Uranium_Enrichment_by_Gas_Centrifuge.pdf ↩

-

https://www.sciencedirect.com/science/article/abs/pii/S0009250921008186 ↩

-

https://isis-online.org/isis-reports/detail/north-koreas-uranium-enrichment-facilities-what-we-learned-from-kcnas-image/ ↩

-

https://www.orano.group/en/nuclear-expertise/from-exploration-to-recycling/international-expert-in-uranium-processing ↩

-

https://www.centrusenergy.com/learn-more/nuclear-fuel-cycle/enrichment/ ↩

-

https://resources.inmm.org/sites/default/files/2021-09/a220.pdf ↩

-

https://www.nuclear-power.com/nuclear-power-plant/nuclear-fuel/nuclear-fuel-cycle/uranium-enrichment/ ↩

-

https://resources.inmm.org/system/files/annual_meeting_proceedings/2018/a161_2.pdf ↩