Introduction to Nuclear Safety

Nuclear power plants are among the most carefully designed and meticulously operated industrial facilities in the world 1. Their safety systems represent a sophisticated approach to risk management that has evolved over more than six decades of civilian nuclear power generation 12. At the heart of nuclear plant protection is the concept of “defence in depth,” a comprehensive safety philosophy that employs multiple independent and redundant layers of protection 3.

This layered approach ensures that if any single safety measure fails, other systems remain in place to prevent harm to the public, workers, and environment 4. The defence in depth strategy incorporates not just physical barriers, but also organizational, procedural, and human elements that work together to create a robust safety ecosystem 5.

Modern nuclear facilities are designed with the understanding that while accidents are extremely unlikely, comprehensive preparations must exist for any contingency 6. These preparations extend from the core design of the reactor itself to emergency response plans for surrounding communities 7.

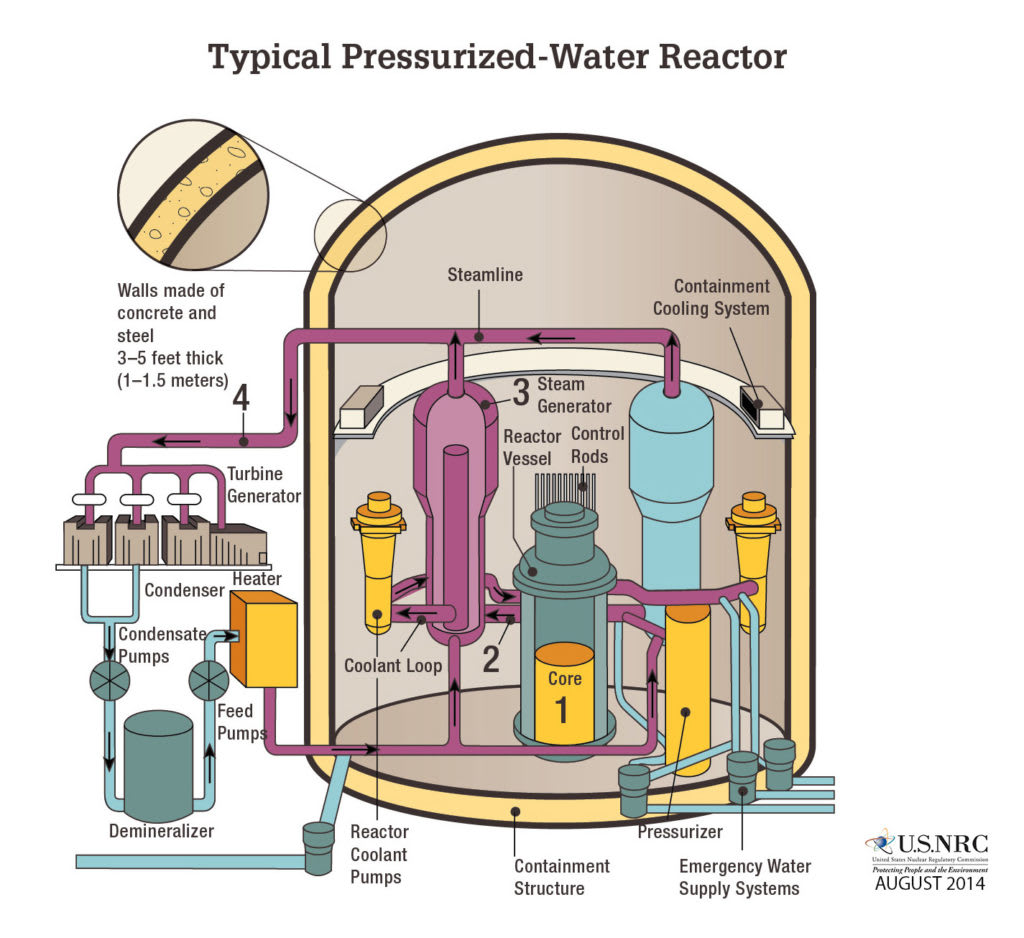

Diagram of a typical pressurized-water reactor, detailing its main components and safety features, including the robust containment structure and emergency cooling systems.

The Multiple Barrier Concept

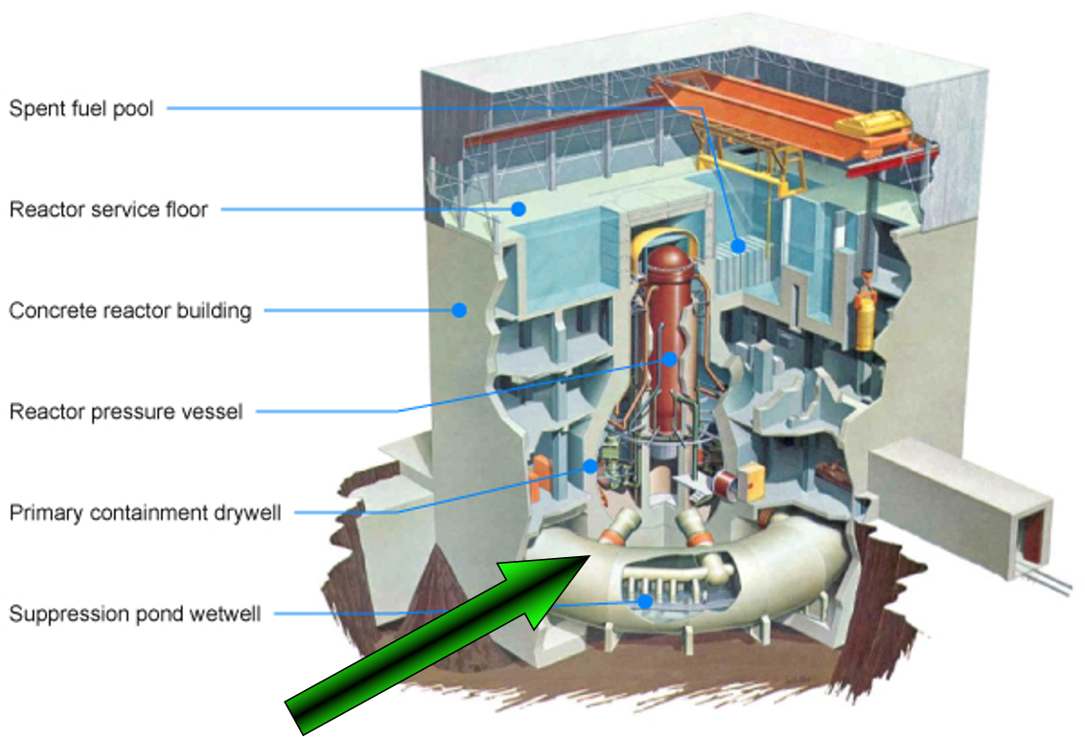

The first line of defence in a nuclear power plant is a series of physical barriers that contain radioactive materials 3. These barriers are designed to work independently so that the failure of one does not compromise the others 8.

The journey begins with the nuclear fuel itself, which is manufactured as ceramic uranium dioxide pellets 9. This material is chosen specifically for its stability and ability to retain most fission products even at high temperatures 10.

Surrounding the fuel pellets is the second barrier: metal cladding made from specialized zirconium alloys 11. This tube-shaped cladding prevents radioactive materials from escaping the fuel during normal operation and most accident scenarios 8.

The third barrier is the reactor pressure vessel and primary coolant system, consisting of thick steel components designed to withstand high pressures and temperatures 12. These heavy-duty components contain the reactor core and circulating coolant 10.

The fourth and most visible barrier is the containment structure—a massive reinforced concrete building with steel liners designed to withstand extreme internal pressures, natural disasters, and even aircraft impacts 13. This impressive structure stands as the final physical barrier between the reactor and the environment 14.

A cutaway diagram illustrating the key components and containment structures within a nuclear reactor building.

Reactor Protection Systems

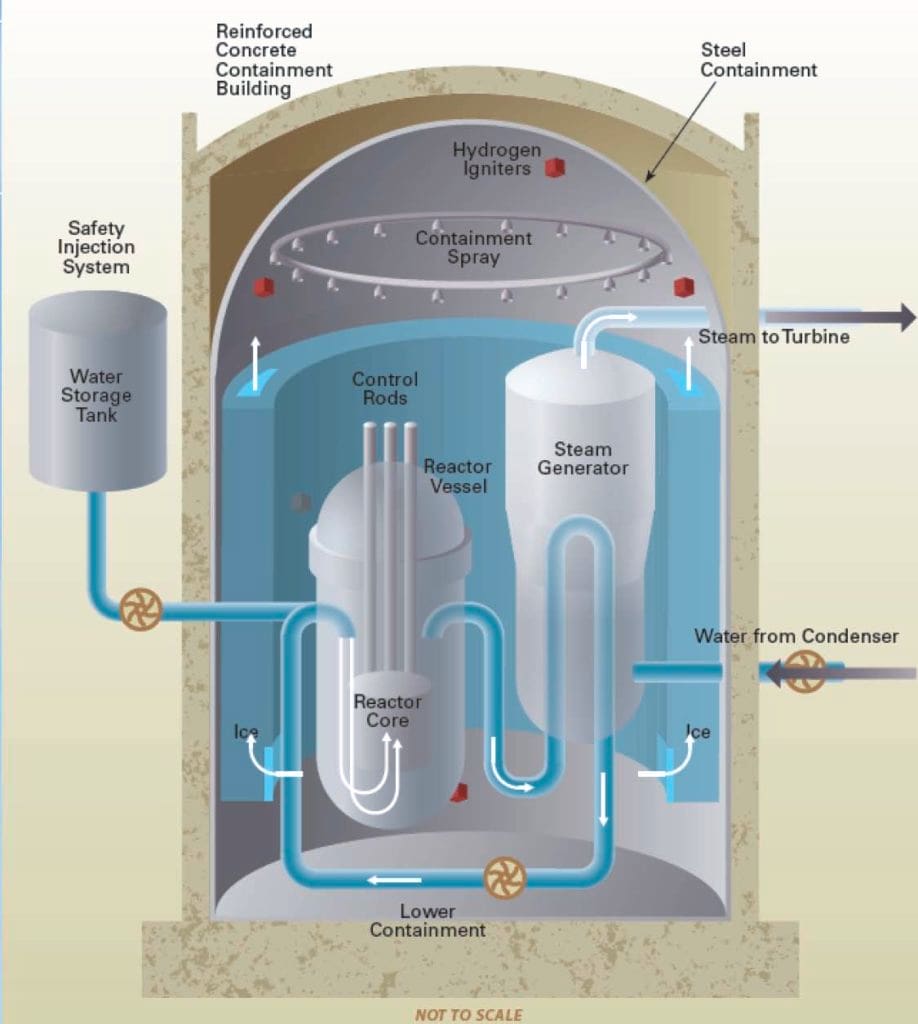

The reactor protection system (RPS) serves as the vigilant guardian of nuclear safety, constantly monitoring critical parameters and ready to trigger an automatic shutdown if unsafe conditions arise 15. This system operates independently from normal control systems, providing a dedicated safety function 152.

Within seconds of detecting abnormal conditions, the RPS can insert control rods into the reactor core to absorb neutrons and halt the nuclear chain reaction 2. This rapid response capability ensures that the reactor can be safely shut down before conditions become dangerous 13.

Modern reactor designs incorporate both active and passive safety systems 16. Active systems rely on pumps, valves, and other mechanical components that require electrical power to function 17. Passive systems, by contrast, use natural forces like gravity, natural circulation, and pressure differences to perform safety functions 18.

The Emergency Core Cooling System (ECCS) represents one of the most critical safety features, designed to provide cooling to the reactor core in the event of a loss of coolant accident (LOCA) 13. Multiple redundant cooling systems ensure that even if primary systems fail, backup systems can maintain core cooling 6.

Diagram illustrating the layered containment structure and key safety systems within a nuclear power plant, including the reactor vessel, steam generator, safety injection system, hydrogen igniters, and containment spray.

Passive Safety Features in Modern Designs

Newer reactor designs have increasingly embraced passive safety features that function without requiring operator actions, AC power, or additional water supplies 19. These systems represent a significant advancement in nuclear safety technology 20.

The AP1000 design by Westinghouse, for example, uses a passive containment cooling system that relies on natural air circulation and gravity-fed water to remove heat from the containment structure 16. This system can function for days without external intervention 21.

Another key passive feature is the automatic depressurization system, which safely reduces pressure in emergency situations by routing steam to spargers submerged in water tanks 19. This prevents damaging pressure buildups that could threaten containment integrity 21.

Small Modular Reactors (SMRs) take passive safety even further, with designs that can maintain cooling indefinitely using natural circulation driven solely by decay heat 20. These advanced features make newer reactors even more resilient against severe accidents 5.

The inherent physics of reactor design also contributes to safety through the negative reactivity coefficient 6. This means that as fuel temperature rises, the nuclear reaction naturally slows down—an inherent safety feature that prevents runaway reactions 6.

Control Room Operations and Monitoring

The control room serves as the command center for the entire nuclear facility, with trained operators constantly monitoring plant parameters and system status 2. Modern control rooms feature advanced human-machine interfaces designed to provide clear information and minimize the potential for human error 22.

Operators undergo rigorous training and licensing requirements before they can take the controls of a nuclear reactor 23. This training includes extensive classroom instruction, hands-on experience, and hundreds of hours in high-fidelity simulators that can replicate any plant condition 23.

Every control room is equipped with redundant monitoring systems and communication capabilities to ensure operators maintain awareness of plant conditions under all circumstances 22. Critical safety parameters are prominently displayed and equipped with alarms to immediately alert operators to potential issues 15.

Following the Three Mile Island accident in 1979, significant improvements were made to control room design, alarm systems, and operator training programs 24. These enhancements focused on improving the clarity of information and reducing operator cognitive load during abnormal conditions 25.

An interior view of a nuclear power plant control room, featuring numerous monitoring consoles and display panels for managing reactor safety systems.

Operator Training and Human Factors

Highly trained personnel are essential to the safe operation of nuclear power plants 23. Operators must hold federal licenses, requiring them to demonstrate both technical knowledge and operational proficiency through rigorous examinations 23.

Initial operator training typically takes 18 months and covers everything from reactor physics and thermodynamics to emergency procedures and plant-specific systems 23. This comprehensive education ensures operators understand not just how to operate the plant, but why specific actions are necessary 26.

Continuing training throughout an operator’s career maintains and enhances these skills 23. Operators typically spend one week in training for every five weeks on shift, practicing responses to normal, abnormal, and emergency conditions in full-scale simulators 23.

These training simulators precisely replicate the actual control room environment and plant behavior, allowing operators to safely practice responding to events that would be impossible to train for in an operating plant 23. This simulation-based training has proven invaluable in preparing personnel for rare but significant events 25.

An operator monitors real-time data and safety parameters in a nuclear power plant control room simulator.

Emergency Planning and Response

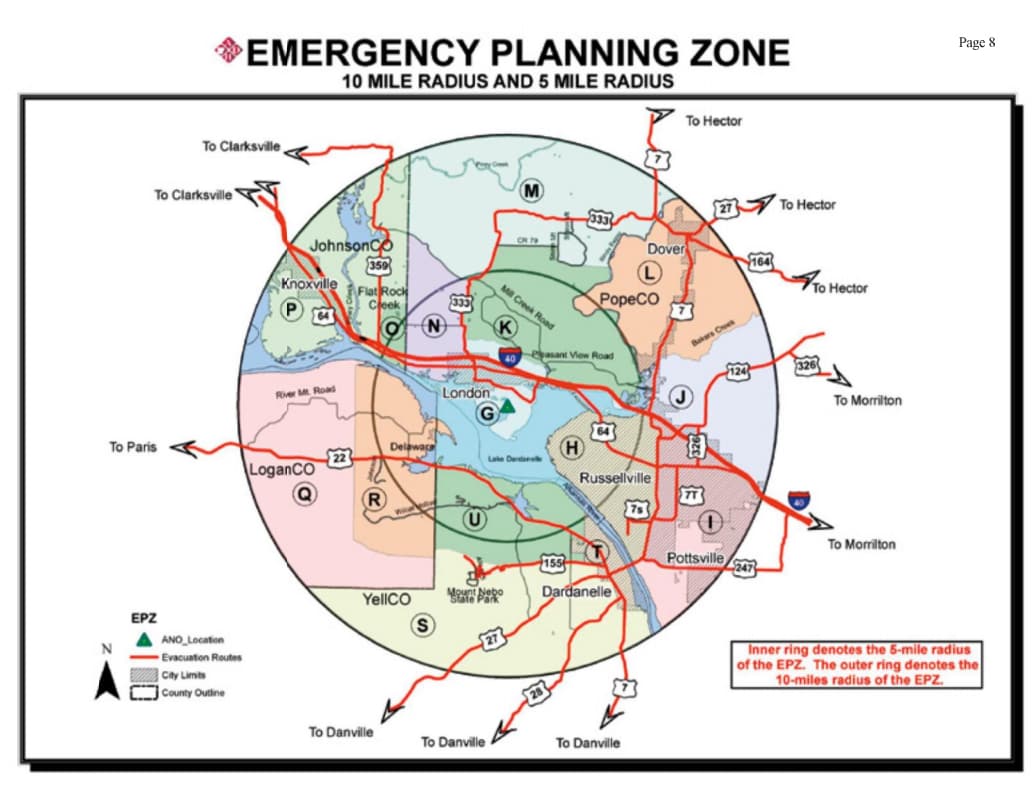

Nuclear facilities maintain comprehensive emergency response plans that extend well beyond the plant boundaries 7. These plans involve coordination between plant personnel, local emergency services, and government agencies at multiple levels 7.

Emergency planning zones are established around each nuclear facility, typically including a 10-mile radius for potential exposure and a 50-mile radius for potential food and water impacts 7. These zones have detailed evacuation routes and public notification systems 7.

Regular drills and exercises test the effectiveness of these plans and the readiness of response organizations 7. These exercises often simulate severe accidents to ensure preparedness for worst-case scenarios 27.

Following the Fukushima accident in 2011, emergency preparedness was further enhanced with additional portable equipment, improved communications systems, and more robust coordination protocols 27. These improvements reflect the industry’s commitment to learning from experience and continuously improving safety measures 5.

Map showing the 5-mile and 10-mile emergency planning zones around the Arkansas Nuclear One facility, including designated evacuation routes.

Physical Security Measures

Nuclear power plants implement multiple layers of physical security to protect against potential threats 28. These measures include robust physical barriers, sophisticated intrusion detection systems, and armed security personnel 29.

The outermost security zone typically features fencing, vehicle barriers, and surveillance systems that establish a secure perimeter around the facility 28. Access to this area is strictly controlled through security checkpoints and personnel screening 30.

Within the protected area, additional security measures safeguard vital equipment and the containment structure 30. Armed security officers patrol these areas and monitor for any unauthorized activities 28.

Security forces at nuclear facilities undergo specialized training and must demonstrate proficiency in responding to various threat scenarios 31. Regular force-on-force exercises test the effectiveness of security plans and personnel against realistic simulated attacks 29.

An armed security guard monitors a facility’s perimeter from inside an observation tower.

Regulatory Oversight and Safety Culture

Independent regulatory bodies, such as the U.S. Nuclear Regulatory Commission (NRC), provide oversight of nuclear facilities to ensure compliance with stringent safety requirements 5. These agencies establish standards, conduct inspections, and enforce regulations designed to protect public health and safety 6.

Regulatory requirements cover every aspect of nuclear plant design, construction, and operation 32. This comprehensive approach ensures that safety is built into nuclear facilities from their earliest design stages and maintained throughout their operational lifetime 5.

Beyond regulatory compliance, the nuclear industry has developed a strong safety culture that prioritizes safe operation above all other considerations 26. This culture emphasizes questioning attitudes, clear communication, and personal accountability at all levels of the organization 26.

Regular assessments of safety culture help identify and address potential weaknesses before they can impact plant safety 26. These assessments look at factors such as decision-making processes, work practices, and organizational values related to safety 26.

Lessons from Past Events: Three Mile Island and Beyond

The Three Mile Island accident in 1979 marked a turning point for nuclear safety in the United States 33. While the event resulted in no injuries or deaths, it revealed significant weaknesses in operator training, control room design, and emergency response capabilities 24.

Following the accident, the nuclear industry implemented comprehensive improvements including enhanced operator training, redesigned control rooms, and improved emergency procedures 33. These changes fundamentally transformed how nuclear plants are operated and managed 25.

The accident demonstrated the effectiveness of defence-in-depth principles, as the containment building successfully prevented significant radiation release despite substantial damage to the reactor core 34. This validated the importance of robust physical barriers as a fundamental safety feature 34.

More recently, the 2011 Fukushima accident in Japan led to additional safety enhancements focused on protecting against extreme external events 27. These included improved flood protection, additional backup power sources, and strategies for maintaining cooling during extended loss of power 27.

Advanced Reactor Safety Systems

Next-generation reactor designs incorporate lessons learned from decades of nuclear operations to create even safer systems 21. These advanced designs often feature simplified safety systems that rely on natural phenomena rather than complex engineered components 20.

Passive safety systems in modern designs can maintain cooling for extended periods without electricity or operator actions 16. This capability addresses one of the key vulnerabilities revealed during the Fukushima accident—the dependence on active cooling systems during loss of power events 19.

Small modular reactors (SMRs) offer inherent safety advantages due to their smaller core size, lower power density, and simplified designs 20. These characteristics reduce the potential consequences of accidents and provide longer response times during abnormal conditions 20.

Advanced reactor designs also incorporate improved instrumentation and control systems that provide operators with clearer information and more time to respond to developing situations 35. These systems help bridge the gap between human capabilities and plant protection requirements 22.

Emergency Planning Zones and Community Protection

Communities surrounding nuclear facilities are protected through detailed emergency plans that include designated evacuation routes, communication systems, and response protocols 7. These plans are developed collaboratively between plant operators, local governments, and emergency management agencies 7.

Emergency planning zones are typically divided into sectors to allow for directed protective actions based on wind direction and other factors 7. This targeted approach helps ensure that appropriate measures can be implemented where they are most needed 7.

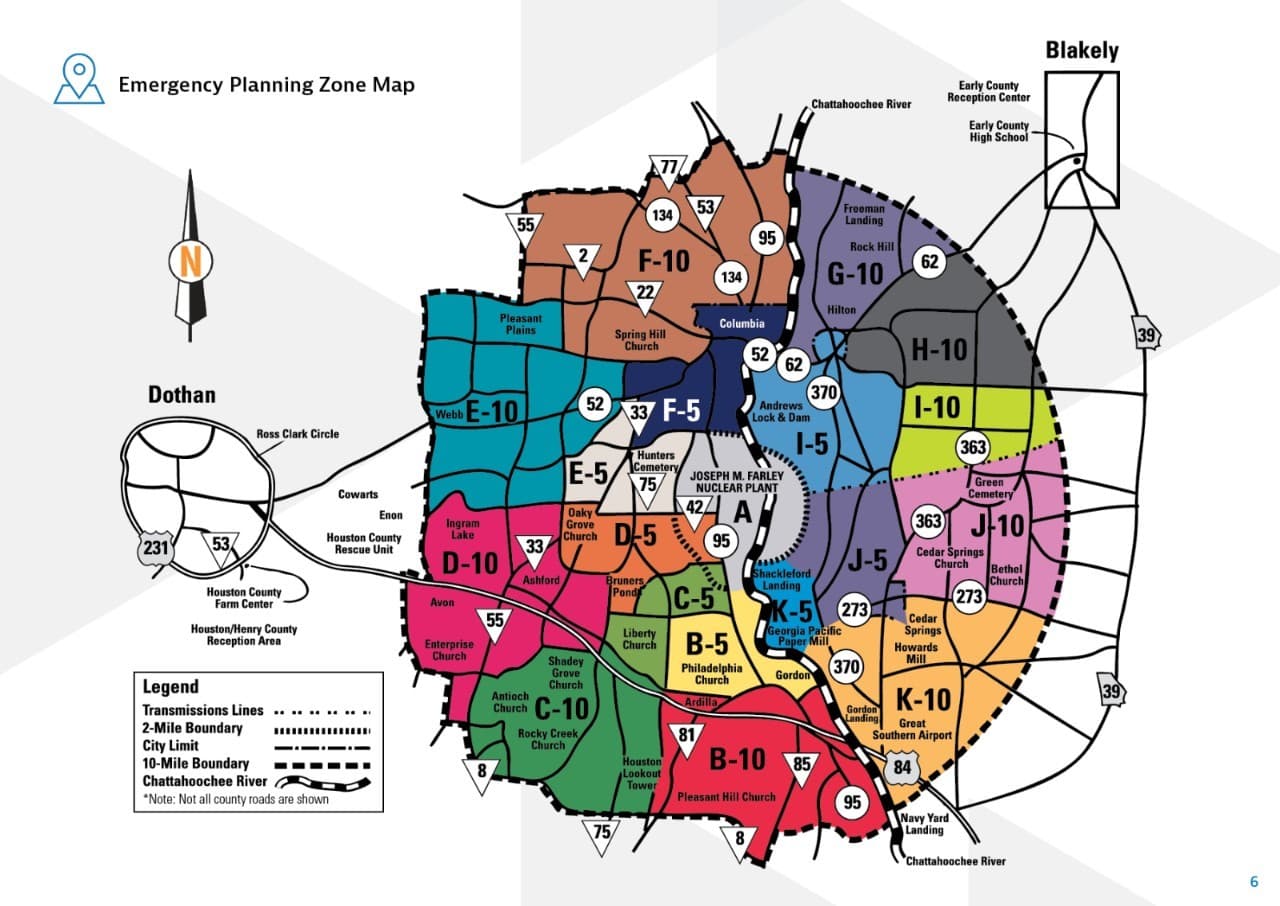

Map showing the emergency planning zones surrounding the Joseph M. Farley Nuclear Plant, detailing areas designated for public protection and emergency response.

Public education programs help ensure that residents understand emergency procedures and know what actions to take if an event occurs 7. Regular communication between plant operators and community stakeholders builds trust and improves emergency preparedness 7.

After the Fukushima accident, many countries reviewed and enhanced their off-site emergency planning capabilities 27. These improvements included better coordination between different levels of government, more robust communication systems, and pre-positioning of emergency equipment 27.

Conclusion: The Future of Nuclear Safety

Defence in depth remains the cornerstone of nuclear safety philosophy, with each new generation of reactors building upon lessons learned from operational experience 5. This approach has resulted in a remarkable safety record for civilian nuclear power, with serious accidents being extremely rare events 1.

Continuing advancements in materials science, computer modeling, and system design are enabling even safer nuclear technologies 35. These innovations promise to further reduce already minimal risks associated with nuclear energy generation 5.

The nuclear industry’s commitment to continuous improvement ensures that safety measures evolve in response to new information, technological capabilities, and potential challenges 1. This dynamic approach to safety helps maintain public confidence in nuclear energy as a reliable and secure power source 6.

As nuclear technology continues to develop, the fundamental principles of defence in depth will remain essential to protecting plants, personnel, and the public 3. Multiple independent barriers, redundant safety systems, and thorough emergency preparations will continue to define the approach to nuclear safety for generations to come 15.

Footnotes

-

https://world-nuclear.org/information-library/safety-and-security/safety-of-plants/safety-of-nuclear-power-reactors ↩ ↩2 ↩3 ↩4 ↩5

-

https://en.wikipedia.org/wiki/Nuclear_reactor_safety_system ↩ ↩2 ↩3 ↩4

-

https://www.nuclear-power.com/nuclear-power/reactor-physics/nuclear-safety/defence-in-depth-principle/ ↩ ↩2 ↩3

-

https://www.nuclear-power.com/how-do-nuclear-power-plants-prevent-accidents/ ↩

-

https://www.energy.gov/ne/enhanced-safety-advanced-reactors ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8

-

https://ant.epri.com/article/nuclear-power-plant-safety ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

https://www.nuclear-power.com/how-do-nuclear-power-plants-prepare-for-emergencies/ ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10 ↩11 ↩12

-

https://www.javys.sk/en/information-service/important-concepts/safety-barriers ↩ ↩2

-

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/654537/3._The_multi-barrier_approach_Proof_6__1_.pdf ↩

-

https://www.nuclear-power.com/nuclear-power/reactor-physics/nuclear-safety/multiple-barriers-to-radionuclide-release/ ↩ ↩2

-

https://www.nuclear-power.com/what-are-the-primary-safety-systems-in-a-nuclear-reactor/ ↩ ↩2 ↩3

-

https://ensi.admin.ch/en/2018/10/31/series-of-articles-on-barriers-barriers-protect-people-and-the-environment-from-radioactive-substances/ ↩

-

https://westinghousenuclear.com/energy-systems/ap1000-pwr/safety/passive-safety-systems/ ↩ ↩2 ↩3

-

https://www.nuclear-power.com/nuclear-power/reactor-physics/nuclear-safety/safety-systems/active-and-passive-nuclear-safety/ ↩

-

https://www.iaea.org/topics/design-safety-nuclear-power-plants/passive-safety-features ↩ ↩2 ↩3

-

https://www.nuscalepower.com/exploring-smrs/smr-101/nuclear-power-and-safety ↩ ↩2 ↩3 ↩4 ↩5

-

https://nuclearstreet.com/nuclear-power-plants/w/nuclear_power_plants/safety-system ↩ ↩2 ↩3

-

https://www.coohom.com/article/nuclear-plant-control-room-layout ↩ ↩2 ↩3

-

https://www.southernnuclear.com/news-center/education/2021-0623-nationalsafety.html ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8

-

https://www.nrc.gov/reading-rm/doc-collections/fact-sheets/3mile-isle.html ↩ ↩2

-

https://www.npr.org/2011/03/28/134914539/its-been-32-years-since-tmis-partial-core-meltdown ↩ ↩2 ↩3

-

https://www.numberanalytics.com/blog/ultimate-guide-safety-culture-nuclear-reactor-safety ↩ ↩2 ↩3 ↩4 ↩5

-

https://www.cnsc-ccsn.gc.ca/eng/resources/fukushima/canada-improvements-post-fukushima/ ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

https://www.nei.org/resources/fact-sheets/nuclear-plant-security-and-access-control ↩ ↩2 ↩3

-

https://www.nrc.gov/reading-rm/doc-collections/fact-sheets/security-enhancements.html ↩ ↩2

-

https://www.nrc.gov/security/domestic/phys-protect.html ↩ ↩2

-

https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1715web-46541668.pdf ↩

-

https://www.nei.org/resources/fact-sheets/lessons-from-1979-accident-at-three-mile-island ↩ ↩2

-

https://world-nuclear.org/information-library/safety-and-security/safety-of-plants/three-mile-island-accident ↩ ↩2

-

https://www.numberanalytics.com/blog/advanced-reactor-protection-systems-enhancing-nuclear-safety ↩ ↩2